Equipment

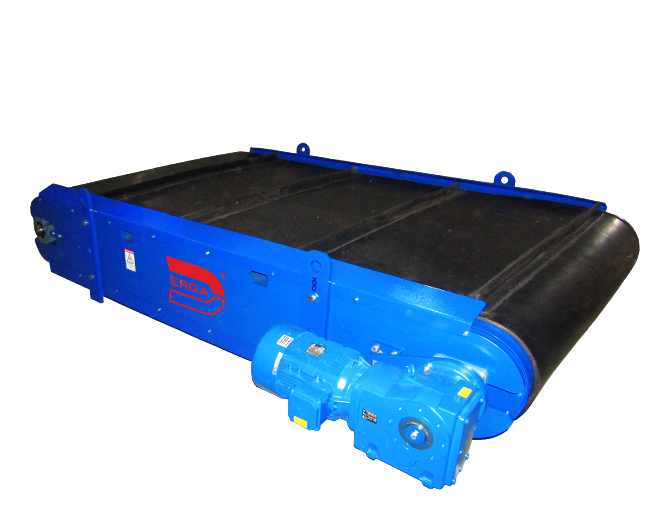

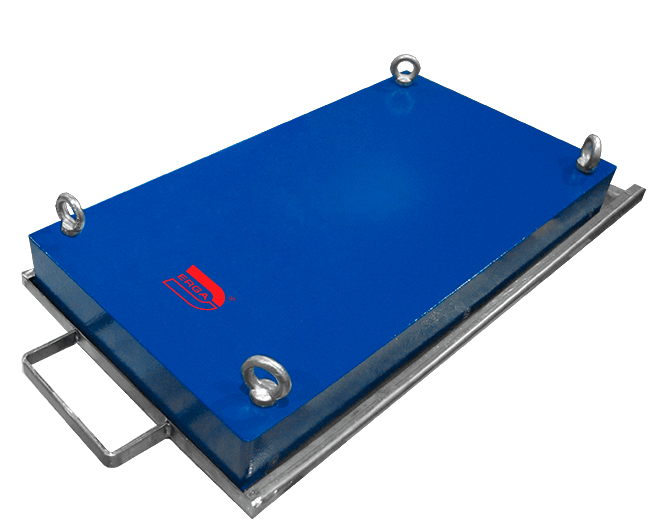

Overbelt self-cleaning magnetic separator ERGA SuspendMag A

-

Efficient operation in harsh conditions

-

Removal area depth up to 550 mm

-

Mass of recovered metal up to 60 kg

-

Powerful permanent magnetic system

Zig zag air separator (pneumatic separator) ERGA ZZFlow

-

Separation/cleaning efficiency up to 99%

-

High throughput

-

Adjustable separation parameters

-

Low power consumption

ERGA ELKRON ESS electrostatic separator

-

Separation/cleaning efficiency up to 99,8%

-

High capacity

-

User-friendly and fast setup

-

Automatic cleaning of electrodes

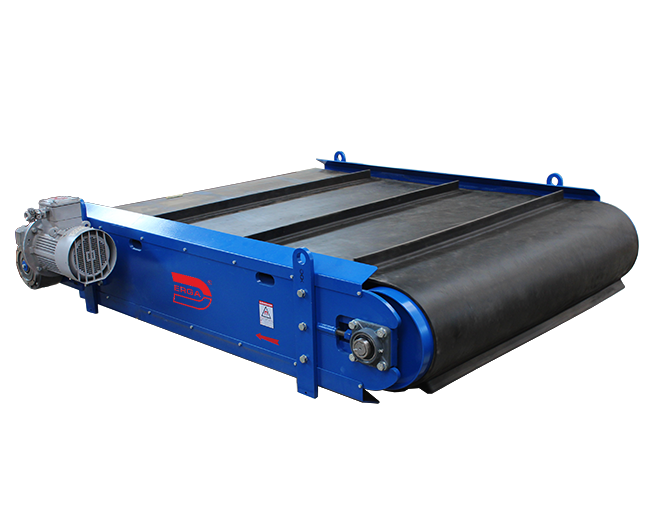

Overbelt magnetic separator ERGA SuspendMag М

-

Efficient recovery of large strongly magnetic impurities

-

Removal area depth up to 450 mm

-

Mass of recovered metal up to 40 kg

-

Easy assembly and operation

Air separation complex Resoline Air Flow for RDF preparation

-

Industry: recycling

-

Raw material: municipal solid waste

-

Size of feed material: up to 150 mm

-

Throughput: up to 20 t/h

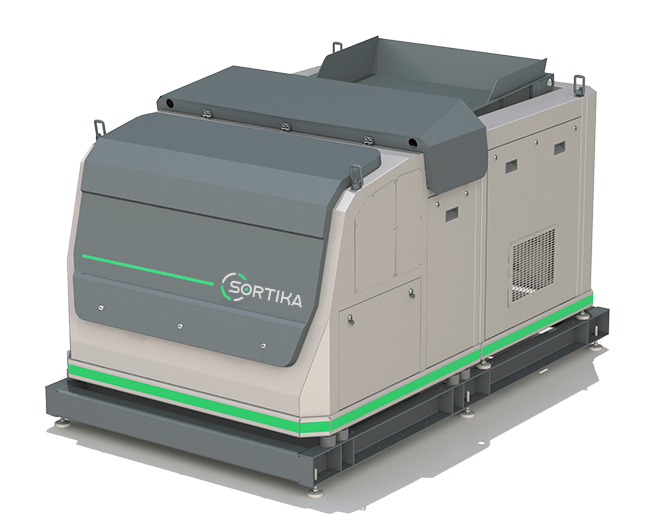

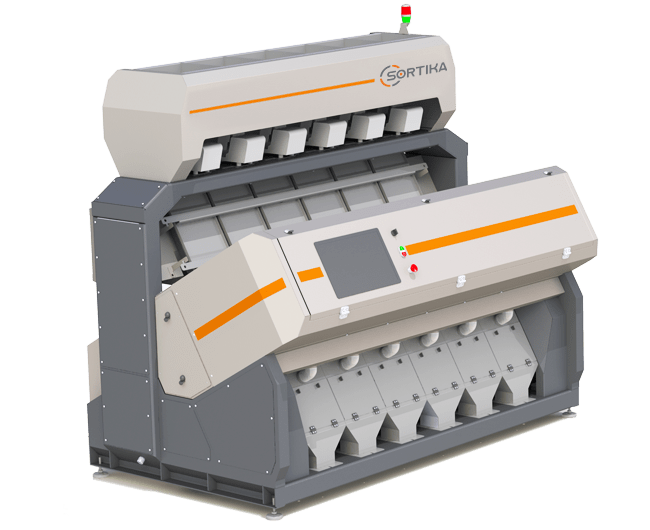

Optical separator LuxSortika VF

-

Separation efficiency up to 99,99%

-

Operation with difficult abrasive materials

-

User-friendly and fast setup

-

Two stages of separation in one housing

Resoline ferrous scrap cleaning line

-

Industry: ferrous metallurgy, recycling

-

Raw material: ferrous scrap

-

Size of feed material: 0-300 mm

-

Capacity: 10 t/h

Resoline crushing and screening complex for processing of steel slag

-

Industry: recycling, ferrous metallurgy, nonferrous metallurgy

-

Raw material: shredder residue (ferrous and nonferrous metal scrap)

-

Size of feed material: 0-300 mm

-

Capacity: 10 t/h

Resoline incineration bottom ash recycling line

-

Industry: MSW treatment

-

Raw material: bottom ash from MSW incineration plant

-

Size of feed material: 0-100 mm

-

Capacity: 15 t/h

Overbelt self-cleaning magnetic separator for MSW ERGA SuspendMag A

-

Increased length of permanent magnetic system

-

Efficient throw of magnetic fraction outside conveyor

-

Removal area depth up to 350 mm

-

Mass of recovered metal up to 30 kg

Eddy current magnetic separator for MSW sorting ERGA EddyFlow VF

-

Recovery of nonferrous metal particles from 2 mm

-

Highly efficient NdFeB magnetic system

-

User-friendly and fast setup

-

Material feed via a vibrating feeder

Magnetic drum separator ERGA DrumMag

-

Permanent magnetic system with induction from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 300 mm to 0.02 mm

-

Automatic cleaning

-

Operation temperature range from -50°С to +50°С

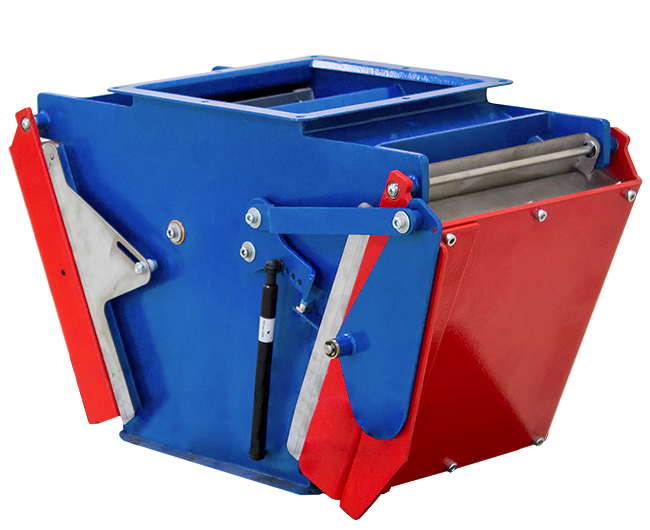

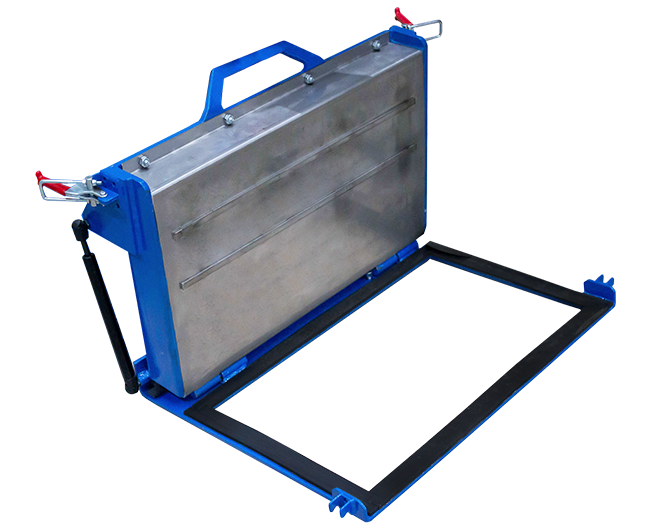

Automatic magnetic plate separator ERGA PlateMag A

-

Production automation

-

Highly efficient magnetic system with magnetic induction up to 0.9 T (9 000 Gauss)

-

Product cleaning efficiency up to 99%

-

Reliable retention of fines

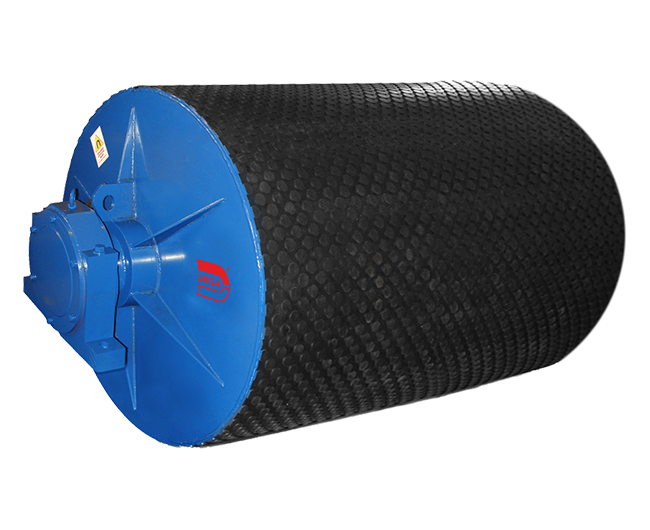

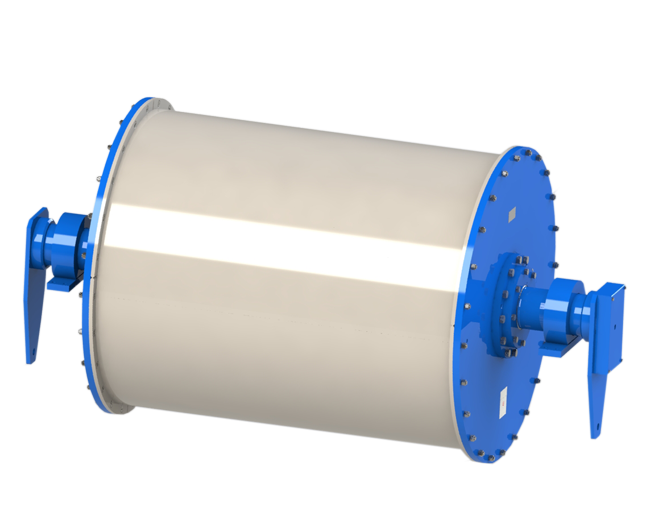

Magnetic pulley ERGA PullMag

-

2 in 1: magnetic iron separator + head pulley

-

Magnetic field operation range up to 350 mm

-

No power consumption

-

Automatic cleaning

Optical separator GlasSortika

-

Obtaining first grade glass scrap

-

24/7 continuous operation

-

Easy and fast customization

-

Two separation stages in a single housing

Resoline nonferrous scrap recycling line

-

Industry: recycling, ferrous metallurgy, nonferrous metallurgy

-

Raw material: shredder residue (ferrous and nonferrous metal scrap)

-

Size of feed material: 0-300 mm

-

Capacity: 5 t/h

Resoline aluminum slag recycling line

-

Industry: nonferrous metallurgy, recycling

-

Raw material: aluminum slag

-

Size of feed material: 2-40 mm

-

Capacity: 5 t/h

Magnetic roll separator ERGA RollMag

-

High quality separation of weakly magnetic minerals

-

Highly efficient NdFeB magnetic system

-

Easy assembly and operation

-

Operating temperatures up to +180°С

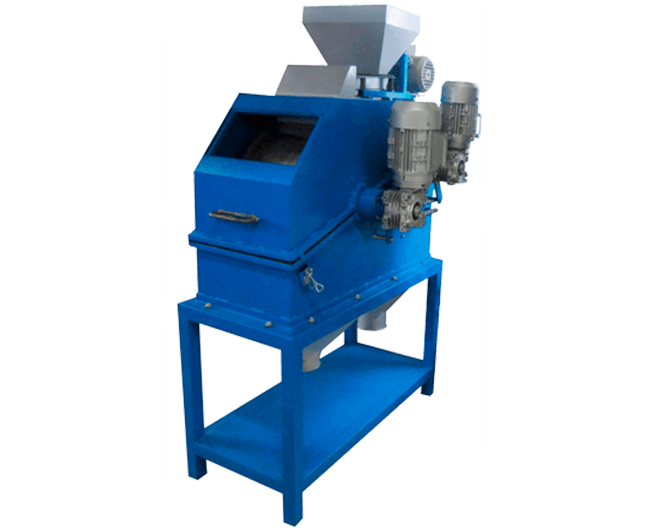

Eddy current magnetic separator with digital control ERGA EddyFlow E5

-

Recovery of metal particles from 3 mm

-

Separation/cleaning efficiency up to 99,8%

-

Highly efficient NdFeB magnetic system

-

Touch Screen intuitive control

Magnetic plate separator ERGA PlateMag 3

-

Off-the-shelf solution: iron separator + elevator boot

-

Highly efficient NdFeB magnetic system

-

Reliable retention of fines

-

Guarantee of end product quality

RESOLINE magnetic and electrostatic concentration and separation line

-

Obtaining high-quality concentrates with purity up to 99,8%

-

Compact automatic complex

-

Dry separation process

-

Wide range of options and settings

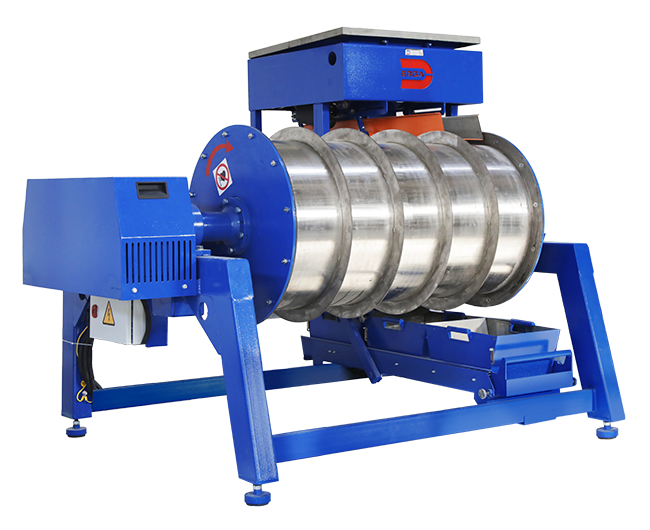

ERGA ELKRON TESS triboelectrostatic separator

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal and mineral particle size from 0.040 to 8 mm

-

One machine for various mixtures

-

High capacity due to enlarged diameter of collecting electrode

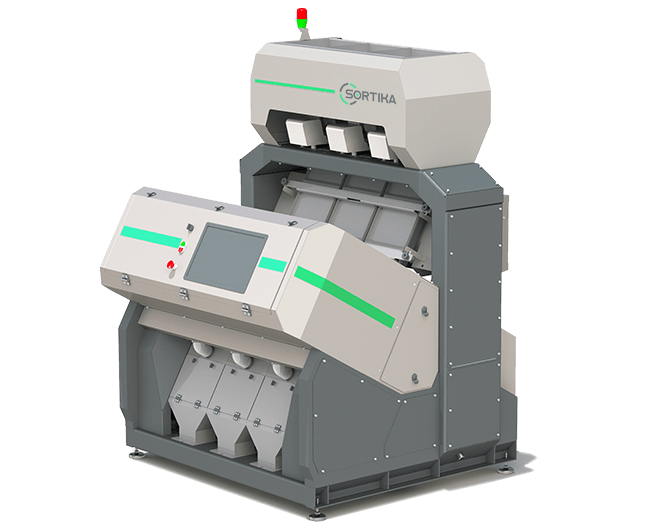

Optical separator LuxSortika CF

-

Efficient separation of minerals less than 10 mm

-

24-7 mineral raw material separation

-

2x productivity increase on the same equipment

-

Up to 3 stages in a single housing

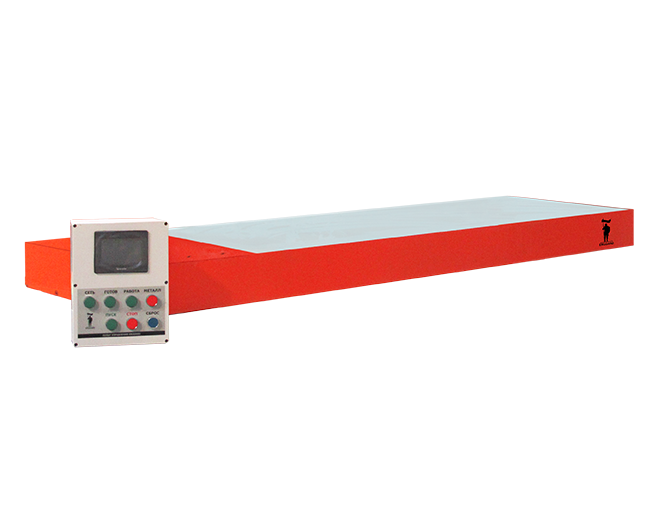

ERGUARD DCM conveyor dismountable metal detector

-

Sectional casing

-

Easy installation

-

High sensitivity to metal inclusions

-

Continuous diagnostics and automatic protection system

Magnetic drum separator ERGA DrumMag M

-

Permanent magnetic system with induction from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 150 mm to 0.02 mm

-

Dust protection

-

Availability of all settings necessary for operation

Eddy current magnetic separators ERGA EddyFlow and EddyFlow E

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal particles from 3 mm

-

User-friendly and fast setup

-

Highly efficient NdFeB magnetic system

Magnetic plate separator ERGA PlateMag 2

-

Integrated solution

-

Compact design of the housing

-

Highly efficient NdFeB magnetic system

-

High capacity of cleaning material

Overbelt magnetic separator ERGA SuspendMag P

-

Optimum solution for simple tasks

-

Removal area depth up to 200 mm

-

Easy assembly and operation

-

Easy cleaning

Optical separator ReSortika CF

-

Effective separation of polymers less than 15 mm

-

Production of cleaned recyclable materials

-

Proprietary software with lifetime tech support

-

Upgrade with 3x performance increase

ERGA PSM-VO magnetic bracket

-

Highly efficient NdFeB magnetic system

-

Unique solution for safety of works

-

Easy installation and operation

-

Efficiency x14 times higher*

ERGUARD SCM conveyor single plate metal detector

-

Compact solution

-

High sensitivity to metal inclusions

-

Protection of crusher, shredder from damage and early wear

-

IP rating of product/sensors: IP54/IP65

Magnetic double-drum separator for dusty products ERGA DrumMag DM

-

Minimum losses of fines during separation

-

Pure magnetic fraction

-

Dry separation method

-

Automatic cleaning

Optical separator LuxSortika BF

-

Efficient separation by mineral composition

-

Preparation of concentrate by dry method

-

Discharge of final tailings

-

Proprietary software with lifetime tech support

Air separator Resoline Air Flow

-

Separation/cleaning efficiency up to 98%

-

Adjustable separation parameters

-

High throughput

-

Low power consumption

Wet magnetic drum separator ERGA WetMag

-

Permanent magnetic system with induction from 0.08 to 0.4 Т

-

Special magnetic system for wet separation process

-

Efficient recovery of magnetic inclusions with size from 0.005 mm to 10 mm

-

Protection of operating surfaces

Magnetic plate separator ERGA PlateMag

-

Integrated solution

-

Highly efficient NdFeB magnetic system

-

Reliable retention of fines

-

Guarantee of end product quality

Optical separator ReSortika BF

-

Efficient separation by composition

-

Proprietary software with lifetime tech support

-

Effective separation of polymers less than 15 mm

-

2 stages of impurity extraction

Wet magnetic drum separator ERGA WetMag R

-

Reduction in expenses for dense-medium solids (magnetite, ferrosilicon)

-

Permanent magnetic system

-

Special design for efficient recovery

-

Customized selection of equipment

Magnetic plate separator ERGA PlateMag V

-

Integrated solution

-

Rugged design of casing for pressurized operation

-

Special NdFeB magnetic system

-

High capacity of cleaning material

ERGA GS gyratory screen

-

Classification efficiency up to 99%

-

Screen mesh size from 0.2mm

-

5 in 1: simultaneous screening into 5 fractions

-

High throughput

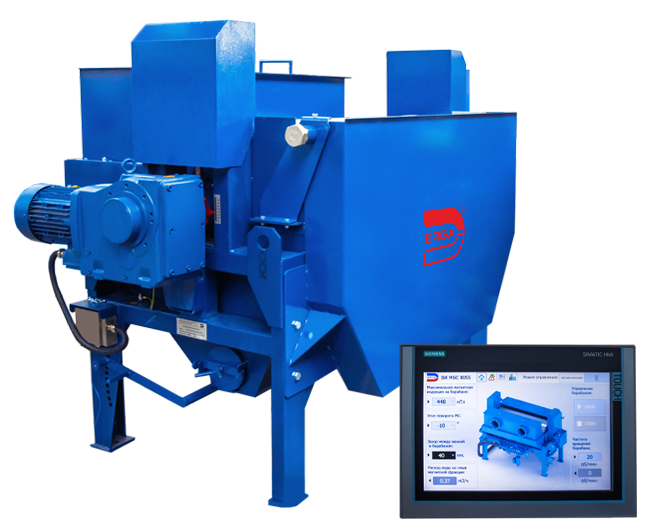

Wet magnetic drum separator ERGA WetMag HI with automated control system

-

Automated adjustment of the permanent magnet system and operation modes

-

Automatic adaptation of separator settings

-

Extremely powerful magnetic system with adjustable induction from 0.1 to 0.6 T

-

Individual selection of magnetic drum size

Wet magnetic drum separator ERGA WetMag HI

-

Extremely powerful magnetic system with induction from 0.3 to 0.6 T

-

Individual selection of magnetic drum size

-

Special magnetic system for wet separation process

-

Wet separation method

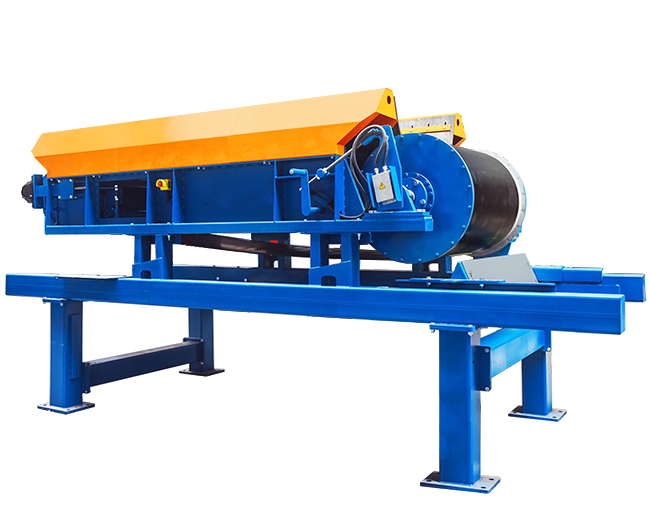

ERGA TS trommel screen

-

High degree of cleaning

-

Efficient screening into 3 fractions

-

Additional automatic cleaning

-

Easy assembly and operation

Conveyor magnetic separator ERGA PullMag C

-

Integrated solution

-

Powerful permanent magnetic system

-

Recovery of inclusions with size up to 350 mm

-

High energy efficiency

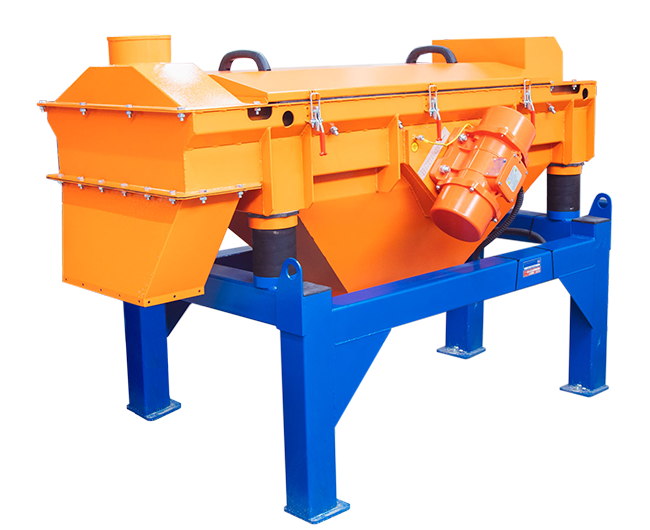

ERGA VS vibrating screen

-

Efficient screening into 4 fractions

-

Robust design and high capacity

-

Quick replacement of screens

-

Optional aspiration

Conveyor magnetic separator ERGA DrumMag C

-

Integrated solution

-

Powerful permanent magnetic system

-

Recovery of magnetic inclusions size up to 300 mm

-

Sectoral magnetic system

ERGA belt conveyors

-

Mobile and stationary conveyors

-

High throughput

-

Bespoke design

-

High class of energy

Magnetic drum separator ERGA DrumMag IC

-

2 in 1: magnetic iron separator + drive pulley

-

Powerful permanent magnetic system

-

Recovery of magnetic inclusions size up to 300 mm

-

Sectoral magnetic system

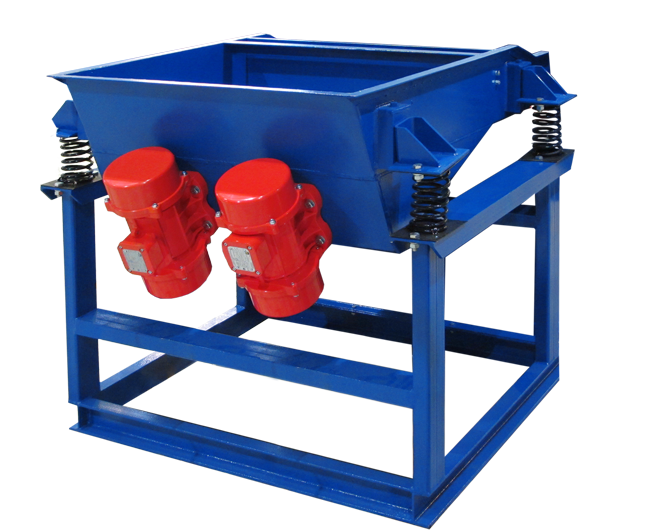

ERGA vibrating feeders

-

Wide range of designs and applications

-

High-strength steel construction

-

Adjustable feed rate and immediate stop

-

Protection of downstream equipment

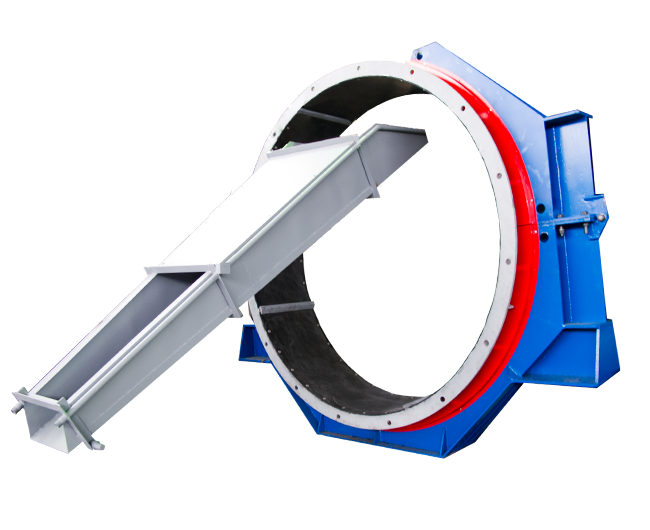

Scrap trap trunnion magnet ERGA TrunMag

-

Continuous diagnostics and automatic protection system

-

Improvement of ore dressing process

-

Customized solution for various mill sizes

-

Easy installation and operation

ERGA dosing hopper

-

Bespoke design

-

Wide range of options and settings

-

Downtime minimization, no bagging

-

Easy installation and operation

REMOS automated remote monitoring system

-

Monitor equipment condition in real time

-

Remote monitoring and control

-

Minimize downtimes

-

Prevent emergency situation and increase your company operation efficiency

Laboratory electrostatic separator ERGA ELKRON ESS

-

Two stages of separation in one housing

-

Separation/cleaning efficiency up to 99,8%

-

Wide range of separation settings

-

Automatic cleaning of electrodes

Laboratory magnetic drum separator ERGA DrumMag

-

Magnetic system with induction from 50 to 900 mТ (500 – 9 000 Gauss)

-

Wide range of separation settings

-

Customized selection of equipment

-

Automatic cleaning

Laboratory magnetic drum separator ERGA DrumMag S

-

Wide range of magnetic induction from 50 to 1 000 mT (500 -10 000 Gauss)

-

Separated material size from 0.1 to 200 mm

-

Automatic cleaning

-

Customized selection of equipment

Laboratory wet magnetic drum separator ERGA WetMag

-

Permanent magnetic system with induction up to 900 mT (9 000 Gauss)

-

Wide range of separation settings

-

Customized selection of equipment

-

Automatic cleaning

Laboratory magnetic roll separator ERGA RollMag

-

Highly efficient NdFeB magnetic system with induction up to 1 700 mТ (17 000 Gauss)

-

Automatic cleaning

-

Customized selection of equipment

-

Wide range of separation settings

Laboratory magnetic double-drum separator ERGA DrumMag M for dusty products

-

Efficient separation of dusty materials

-

Sealed housing

-

Highly efficient NdFeB magnetic system with induction up to 900 mT

-

Automatic cleaning

Laboratory dry separation complex ERGA DrumMag-RollMag

-

2 in 1: drum and roll separators in one plant

-

Ideal solution for recovery of rough concentrates

-

Automatic cleaning

-

Customized selection of equipment

Magnetic probe MP

-

Highly efficient NdFeB magnetic system with induction up to 900 mT

-

Easy to operate and maintain

-

Incoming and intermediate inspections

-

Affordable price

At the first stage of the permanent magnet production, the raw materials are sorted and delivered to the melting shop. Iron, neodymium, ferroboron (or samarium, cobalt) and other necessary components are fed into the melting furnace and melted in argon. The furnace gradually heats up to1500 ° C, the temperature at which the raw materials melt.

In 40 minutes the alloy will be almost ready; it only needs to be cooled. Ingot of material is removed from the mold, powder is subsequently obtained from ingots to manufacture permanent magnets. The alloy must be crushed to from powder ranging about 5 microns. To obtain the powder of the desired fraction, the ingots are treated in three types of mills: coarse, medium grinding and pulverizing. Every machine grinds up to 200 kg of metal per work shift.

The finished powder consists of micromagnets ranging no more than 5 microns. Under the press, the mass gets the desired shape, and its constituent particles - orientation in the magnetic field. The powder is compacted in magnetic field. The result is a magnet press blank.

The blank is immediately placed in a vacuum bag: the alloy powder is oxidized in open air, which means that its magnetic properties change. In addition, powders can ignite at any moment. The blank will remain in the protective film until the moment of sintering. The temperature inside the oven reaches 1200 °C. The magnets are sintered and heat-treated for up to 3-4 days. During this time, the micromagnets in the alloy will be compacted and get monolithic shape. Only now the bars are ready to turn into permanent magnets.

See also