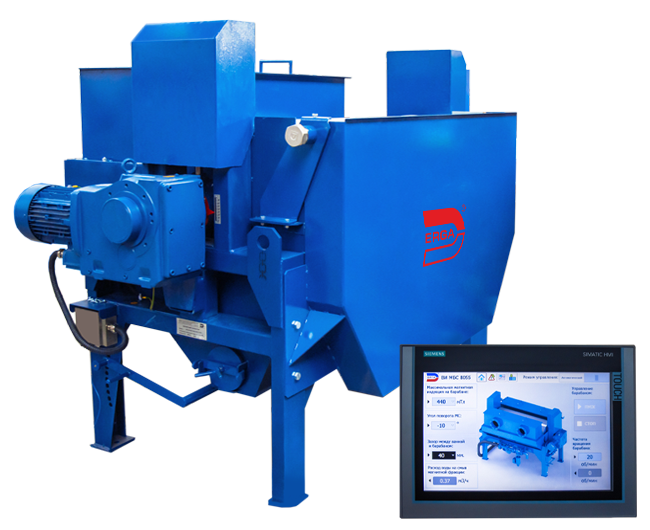

Wet magnetic drum separator ERGA WetMag HI with automated control system

Wet magnetic separator with automated control system for continuous concentration of ores and nonmetallic materials

-

Automated adjustment of the permanent magnet system and operation modes

-

Automatic adaptation of separator settings

-

Extremely powerful magnetic system with adjustable induction from 0.1 to 0.6 T

-

Individual selection of magnetic drum size

-

LSC integration

-

Option of integration into SCADA system of the enterprise

-

Automatic protection in emergency situations

-

Pre-alarm and alarm signaling of deviations in main process parameters

-

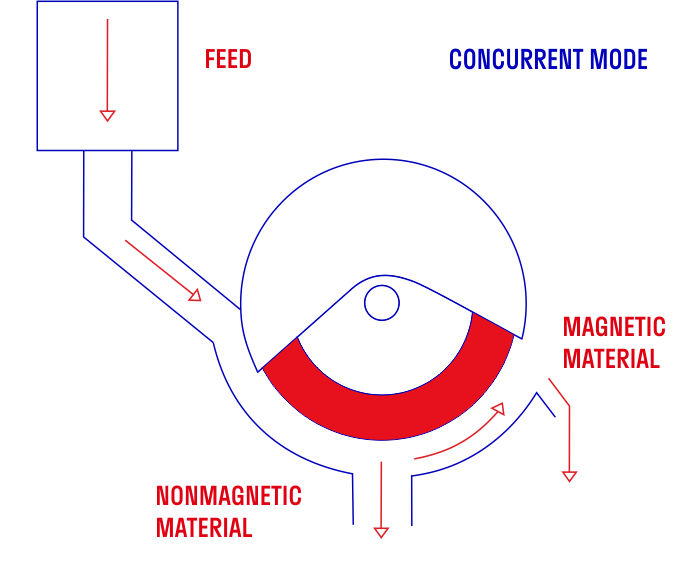

Wet separation method

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

Self-discharging ERGA WetMag HI permanent magnetic drum separator is designed for automatic continuous recovery of medium and magnetic inclusions from slurries and process media.

- Automated adjustment of the permanent magnet system and operation modes

Parameters of magnetic induction, degrees rotation of magnetic system and gap between the tank and the drum are set and adjusted on the control touch pad or from the operator's workstation.

• Adjustment of magnetic intensity on the drum

Option of adjustment of magnetic field intensity (induction) on the drum shell surface provides adaptation to changes in ore composition, while maintaining high concentration rates.

• Adjustment of degrees rotation of magnetic system

Option of adjusting the degrees rotation of magnetic system ensures setting optimum position of the magnetic poles for complete discharge of the magnetic fraction from the drum, which ensures efficient discharge of the magnetic fraction and reduces shell wear.

• Adjustment of the gap between the tank and the drum

Option of adjusting the gap between the magnetic drum and the bottom of the bath of the product allows you to stabilize the level of pulp flow in the bath when changing the productivity of the input material in order to maintain high enrichment rates.

- Automatic adaptation of separator settings

In addition to the basic control settings, the equipment has automatic adaption option thanks to which changing one of the product settings does not affect others. For example, when magnetic field intensity is changed, the magnetic concentrate discharge position will not change due to the automatic adaptation of the angle of rotation of the magnetic system; when the size of the gap between the magnetic drum shell and the tank changes, the position of magnetic concentrate discharge will not change due to the automatic adaptation of the angle of rotation of the magnetic system.

- Extremely powerful permanent magnetic system

Magnetic field parameters are individually selected depending on magnetic susceptibility of the material for separation and vary from 0.1 to 0.6 T.

The magnetic system features are deep magnetization of the operating zone for maximum recovery of magnetic particles and high-intensity magnetic stirring for breaking magnetic floccules and receiving magnetic concentrate.

ERGA WetMag HI is used in concentration of oxidized iron, chromium, nonferrous, gold-bearing ores, tailings of concentration plants, etc. for recovery of minerals with medium and low magnetic susceptibility.

- Individual selection of magnetic drum size

Flexibility of engineering and manufacturing process provides customized solutions for Customer’s required technological parameters (process performance, installation site features).

The drum parameters can vary with diameter from 250 to 900 mm and length from 100 to 2000 mm.

- Wet separation method

Application of WetMag HI drum separators is cost-effective and efficient with wet process of concentration. The wet separation process allows for processing of a wide range of particle sizes to produce high-quality saleable magnetic concentrate.

- Protection of operating surfaces

Wear-prone separator parts (bath, rolls) are lined with special wear-resistant coatings. Separator covers, electrical cabinets are made of stainless steel, have increased reliability and wear resistance.

- Touch Screen intuitive control

Complete digital control is with control panel having a 10-inch high-definition touch screen with user-friendly interface. Continuous, uninterrupted, centralized control and monitoring of the process conditions and technological parameters is in real time in automated mode.

Remote control mode is available from the operator's workstation.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.