Separators

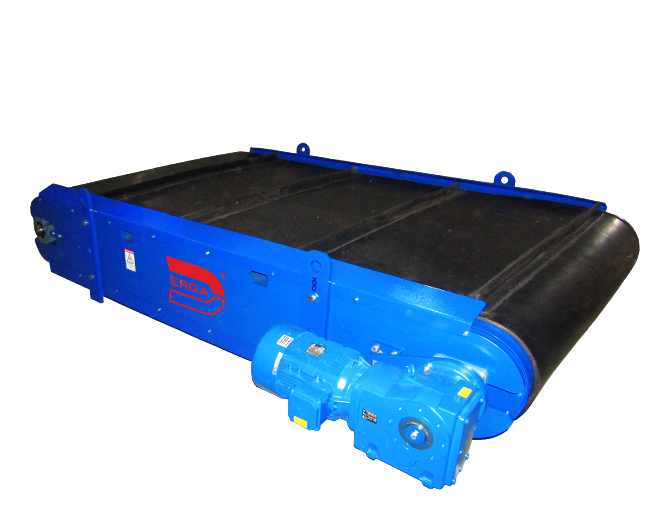

Overbelt self-cleaning magnetic separator ERGA SuspendMag A

-

Efficient operation in harsh conditions

-

Removal area depth up to 550 mm

-

Mass of recovered metal up to 60 kg

-

Powerful permanent magnetic system

Zig zag air separator (pneumatic separator) ERGA ZZFlow

-

Separation/cleaning efficiency up to 99%

-

High throughput

-

Adjustable separation parameters

-

Low power consumption

ERGA ELKRON ESS electrostatic separator

-

Separation/cleaning efficiency up to 99,8%

-

High capacity

-

User-friendly and fast setup

-

Automatic cleaning of electrodes

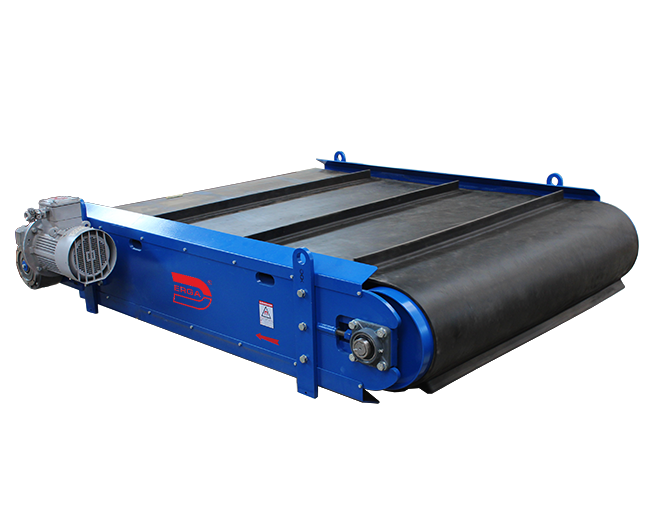

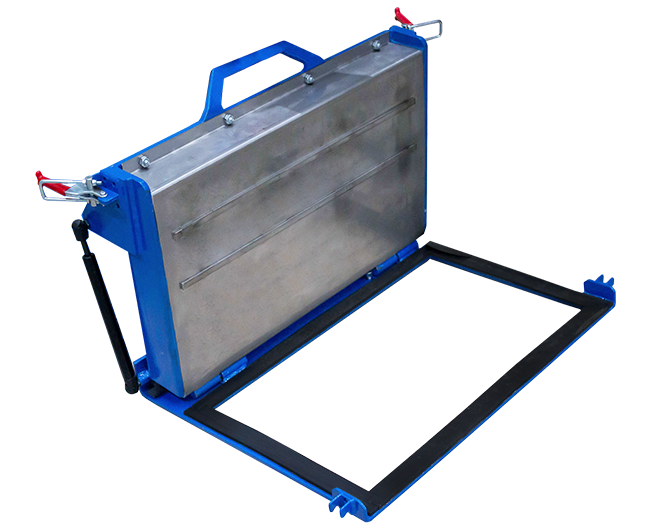

Overbelt magnetic separator ERGA SuspendMag М

-

Efficient recovery of large strongly magnetic impurities

-

Removal area depth up to 450 mm

-

Mass of recovered metal up to 40 kg

-

Easy assembly and operation

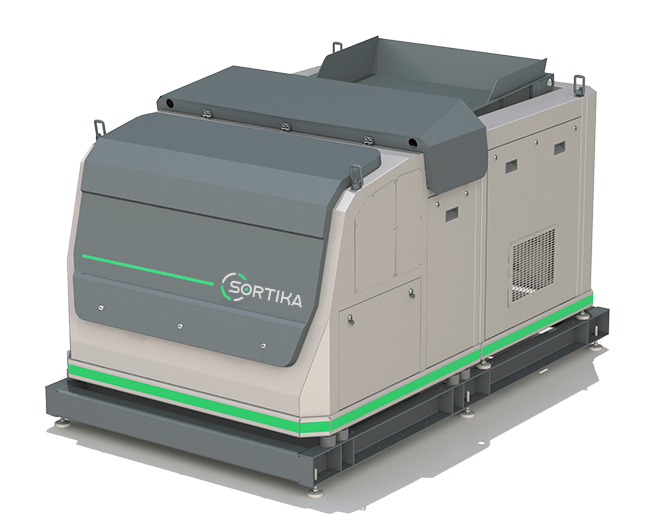

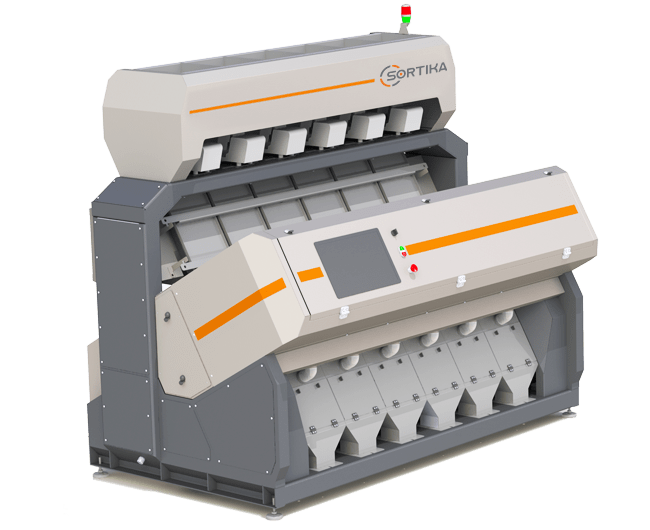

Optical separator LuxSortika VF

-

Separation efficiency up to 99,99%

-

Operation with difficult abrasive materials

-

User-friendly and fast setup

-

Two stages of separation in one housing

Overbelt self-cleaning magnetic separator for MSW ERGA SuspendMag A

-

Increased length of permanent magnetic system

-

Efficient throw of magnetic fraction outside conveyor

-

Removal area depth up to 350 mm

-

Mass of recovered metal up to 30 kg

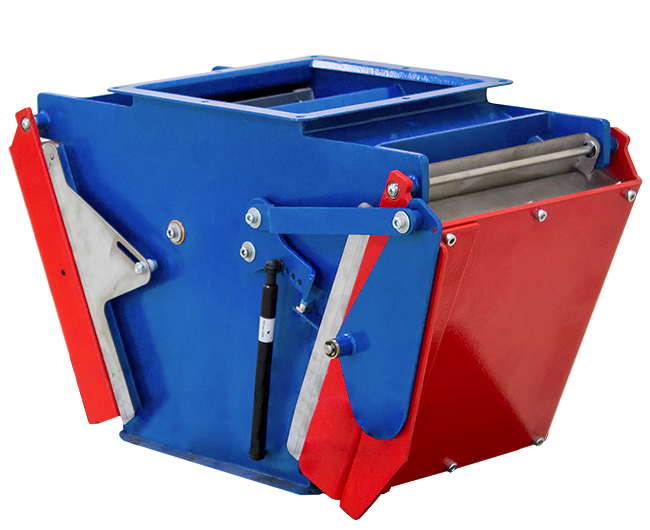

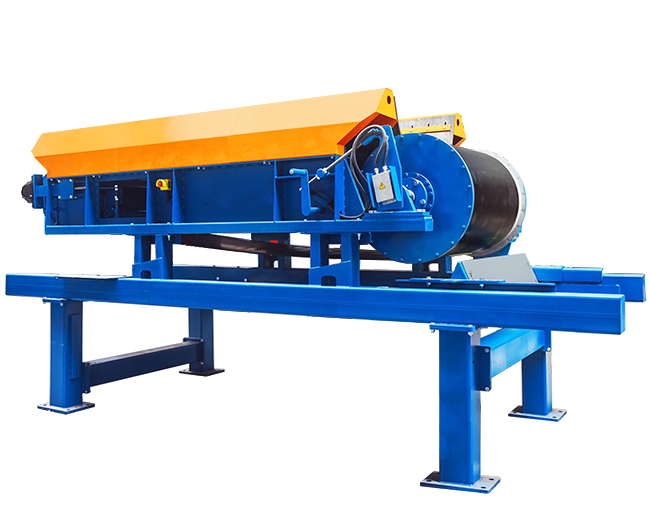

Eddy current magnetic separator for MSW sorting ERGA EddyFlow VF

-

Recovery of nonferrous metal particles from 2 mm

-

Highly efficient NdFeB magnetic system

-

User-friendly and fast setup

-

Material feed via a vibrating feeder

Magnetic drum separator ERGA DrumMag

-

Permanent magnetic system with induction from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 300 mm to 0.02 mm

-

Automatic cleaning

-

Operation temperature range from -50°С to +50°С

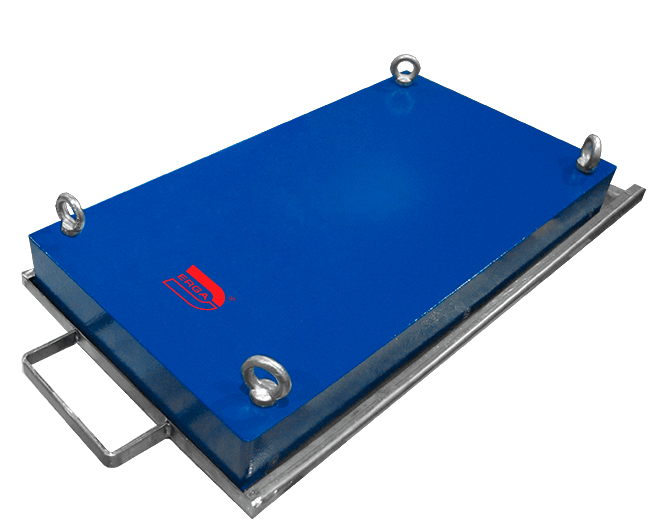

Automatic magnetic plate separator ERGA PlateMag A

-

Production automation

-

Highly efficient magnetic system with magnetic induction up to 0.9 T (9 000 Gauss)

-

Product cleaning efficiency up to 99%

-

Reliable retention of fines

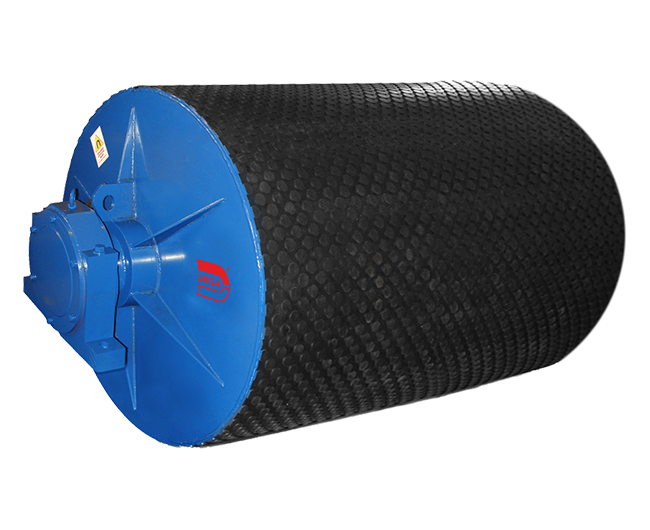

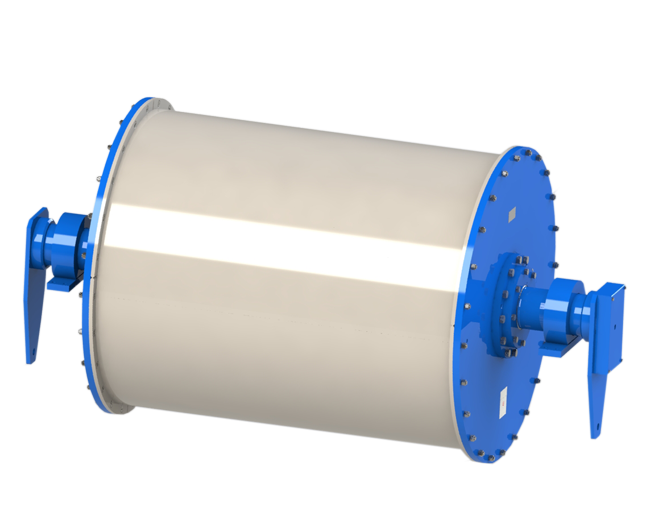

Magnetic pulley ERGA PullMag

-

2 in 1: magnetic iron separator + head pulley

-

Magnetic field operation range up to 350 mm

-

No power consumption

-

Automatic cleaning

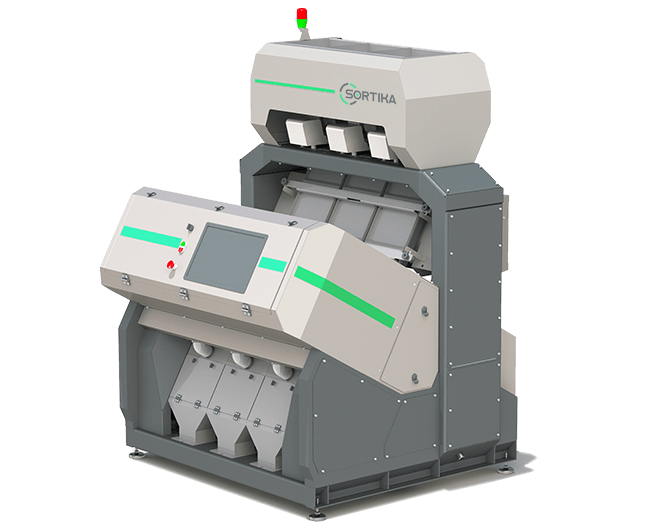

Optical separator GlasSortika

-

Obtaining first grade glass scrap

-

24/7 continuous operation

-

Easy and fast customization

-

Two separation stages in a single housing

Magnetic roll separator ERGA RollMag

-

High quality separation of weakly magnetic minerals

-

Highly efficient NdFeB magnetic system

-

Easy assembly and operation

-

Operating temperatures up to +180°С

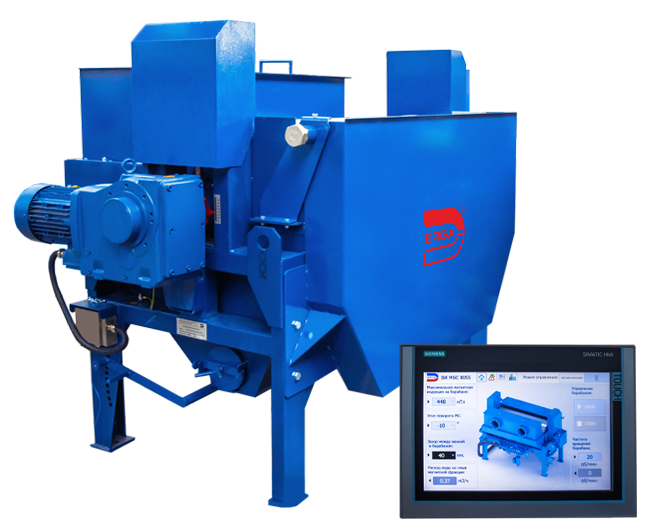

Eddy current magnetic separator with digital control ERGA EddyFlow E5

-

Recovery of metal particles from 3 mm

-

Separation/cleaning efficiency up to 99,8%

-

Highly efficient NdFeB magnetic system

-

Touch Screen intuitive control

Magnetic plate separator ERGA PlateMag 3

-

Off-the-shelf solution: iron separator + elevator boot

-

Highly efficient NdFeB magnetic system

-

Reliable retention of fines

-

Guarantee of end product quality

ERGA ELKRON TESS triboelectrostatic separator

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal and mineral particle size from 0.040 to 8 mm

-

One machine for various mixtures

-

High capacity due to enlarged diameter of collecting electrode

Optical separator LuxSortika CF

-

Efficient separation of minerals less than 10 mm

-

24-7 mineral raw material separation

-

2x productivity increase on the same equipment

-

Up to 3 stages in a single housing

Magnetic drum separator ERGA DrumMag M

-

Permanent magnetic system with induction from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 150 mm to 0.02 mm

-

Dust protection

-

Availability of all settings necessary for operation

Eddy current magnetic separators ERGA EddyFlow and EddyFlow E

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal particles from 3 mm

-

User-friendly and fast setup

-

Highly efficient NdFeB magnetic system

Magnetic plate separator ERGA PlateMag 2

-

Integrated solution

-

Compact design of the housing

-

Highly efficient NdFeB magnetic system

-

High capacity of cleaning material

Overbelt magnetic separator ERGA SuspendMag P

-

Optimum solution for simple tasks

-

Removal area depth up to 200 mm

-

Easy assembly and operation

-

Easy cleaning

Optical separator ReSortika CF

-

Effective separation of polymers less than 15 mm

-

Production of cleaned recyclable materials

-

Proprietary software with lifetime tech support

-

Upgrade with 3x performance increase

Magnetic double-drum separator for dusty products ERGA DrumMag DM

-

Minimum losses of fines during separation

-

Pure magnetic fraction

-

Dry separation method

-

Automatic cleaning

Optical separator LuxSortika BF

-

Efficient separation by mineral composition

-

Preparation of concentrate by dry method

-

Discharge of final tailings

-

Proprietary software with lifetime tech support

Air separator Resoline Air Flow

-

Separation/cleaning efficiency up to 98%

-

Adjustable separation parameters

-

High throughput

-

Low power consumption

Wet magnetic drum separator ERGA WetMag

-

Permanent magnetic system with induction from 0.08 to 0.4 Т

-

Special magnetic system for wet separation process

-

Efficient recovery of magnetic inclusions with size from 0.005 mm to 10 mm

-

Protection of operating surfaces

Magnetic plate separator ERGA PlateMag

-

Integrated solution

-

Highly efficient NdFeB magnetic system

-

Reliable retention of fines

-

Guarantee of end product quality

Optical separator ReSortika BF

-

Efficient separation by composition

-

Proprietary software with lifetime tech support

-

Effective separation of polymers less than 15 mm

-

2 stages of impurity extraction

Wet magnetic drum separator ERGA WetMag R

-

Reduction in expenses for dense-medium solids (magnetite, ferrosilicon)

-

Permanent magnetic system

-

Special design for efficient recovery

-

Customized selection of equipment

Magnetic plate separator ERGA PlateMag V

-

Integrated solution

-

Rugged design of casing for pressurized operation

-

Special NdFeB magnetic system

-

High capacity of cleaning material

Wet magnetic drum separator ERGA WetMag HI with automated control system

-

Automated adjustment of the permanent magnet system and operation modes

-

Automatic adaptation of separator settings

-

Extremely powerful magnetic system with adjustable induction from 0.1 to 0.6 T

-

Individual selection of magnetic drum size

Wet magnetic drum separator ERGA WetMag HI

-

Extremely powerful magnetic system with induction from 0.3 to 0.6 T

-

Individual selection of magnetic drum size

-

Special magnetic system for wet separation process

-

Wet separation method

Conveyor magnetic separator ERGA PullMag C

-

Integrated solution

-

Powerful permanent magnetic system

-

Recovery of inclusions with size up to 350 mm

-

High energy efficiency

Conveyor magnetic separator ERGA DrumMag C

-

Integrated solution

-

Powerful permanent magnetic system

-

Recovery of magnetic inclusions size up to 300 mm

-

Sectoral magnetic system

Magnetic drum separator ERGA DrumMag IC

-

2 in 1: magnetic iron separator + drive pulley

-

Powerful permanent magnetic system

-

Recovery of magnetic inclusions size up to 300 mm

-

Sectoral magnetic system

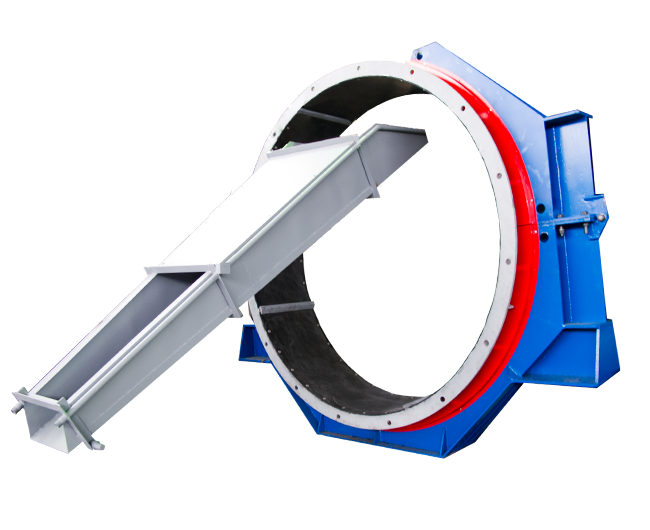

Scrap trap trunnion magnet ERGA TrunMag

-

Continuous diagnostics and automatic protection system

-

Improvement of ore dressing process

-

Customized solution for various mill sizes

-

Easy installation and operation