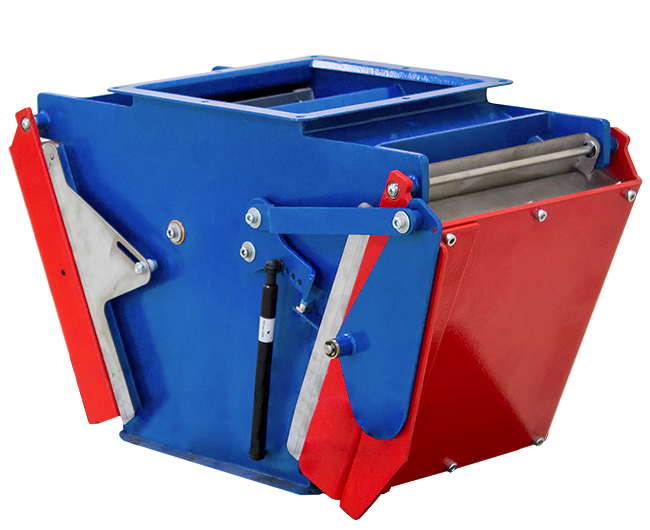

Automatic magnetic plate separator ERGA PlateMag A

Automatic magnetic plate separator for cleaning bulk products from metal impuritites

-

Production automation

-

Highly efficient magnetic system with magnetic induction up to 0.9 T (9 000 Gauss)

-

Product cleaning efficiency up to 99%

-

Reliable retention of fines

-

Automatic and on-time cleaning: 5-10 seconds

-

Guarantee of end product quality

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

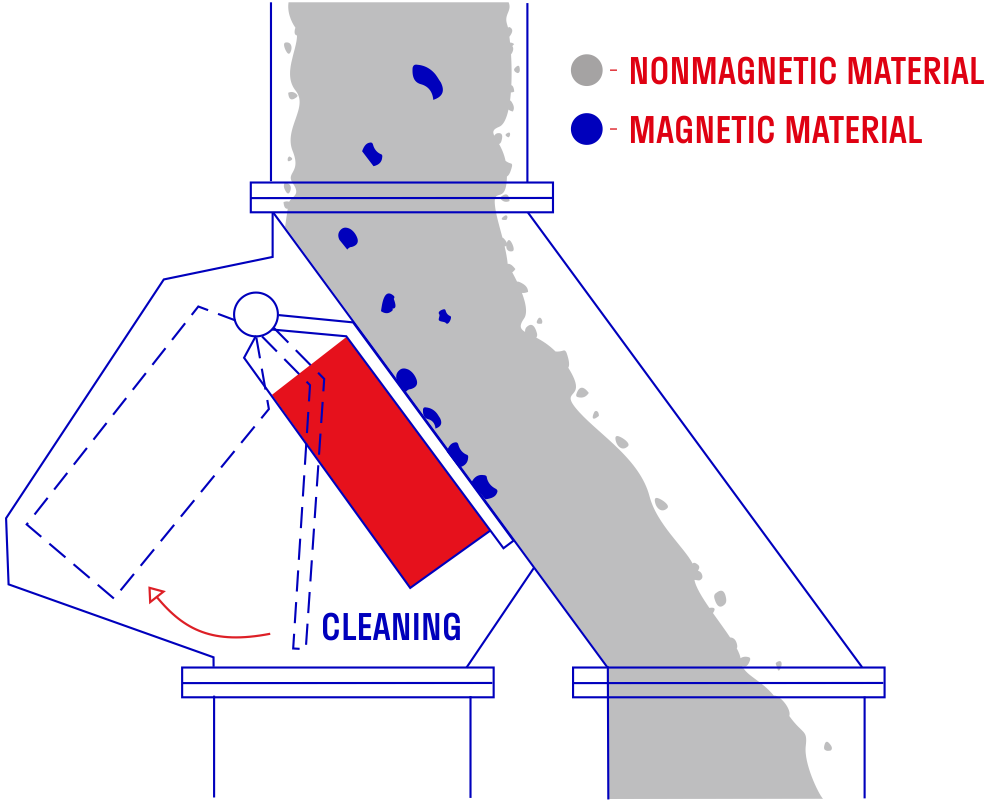

Operation Principle

Industries

Automatic plate iron separator ERGA PlateMag A is installed in a gravity circular or rectangular pipeline and ensures efficient and proper separation of metal contaminants from the bulk flow.

- Production automation

Equipment with an automatic cleaning system allows you to automate production, eliminating the human factor, equipment downtime and associated costs.

- Product cleaning efficiency up to 99%

Individual separation mode is selected depending on material and requirements to the end product. Powerful magnetic system with induction up to 0.9 T (9 000 Gauss), fine setting of cleaning intervals achieve up to 99% separation efficiency.

- Reliable retention of fines

Work surfaces of the magnetic plates are equipped with special ribs forming the so-called shadow zones, necessary for reliable retention of metal fines and preventing their flow with the rest of material.

- Automatic and on-time cleaning: 5-10 seconds

The iron separator is controlled by operation cycles changing with metal inclusions discharge. Automatic cleaning is carried out after stopping the product flow, it takes 5-10 seconds without any personnel involvement. The retained magnetic impurities are discharged into the outlet pipe. >> You can learn more about PlateMag A operation principle in the VIDEO block.

- Guarantee of end product quality

ERGA PlateMag A self-clean plate iron separator with a powerful magnetic system increases the volume of production of quality products, eliminating defects and claims, confirming the reputation of a reliable partner and manufacturer. ERGA PlateMag A iron separators are commonly applied at food processing facilities with their strict requirements to food quality control and safety management system based on HACCP principles.

- Conformity with industrial safety regulations

The equipment corresponds to the requirements of industrial safety regulations and rules valid and can be applied at food, explosive (including vegetable stock storage, processing and utilization facilities) and chemically hazardous enterprises and facilities. All required certificates are included in the scope of supply.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced ERGA PlateMag A magnetic plate separators are given in table. Customized solutions can be designed according to the order requirements. The guaranteed shelf life of the magnetic system properties, subject to operating rules, is 10 years.

| Model | Dimensions (LxWxH), mm | Magnetic induction on the working surface , mT | Weight, kg |

|---|---|---|---|

| PlateMag A 300х300 | 940х600х570 | up to 0,9 | 120 |

| PlateMag A 400х400 | 1100х700х650 | up to 0,9 | 160 |

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor