Magnetic separators

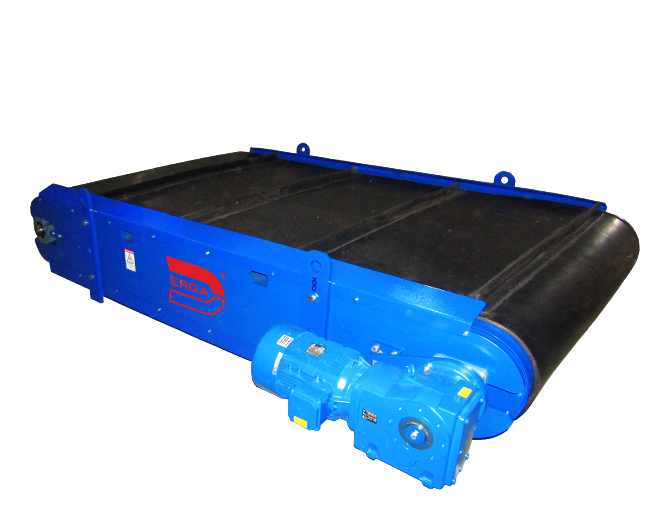

Overbelt self-cleaning magnetic separator ERGA SuspendMag A

-

Efficient operation in harsh conditions

-

Removal area depth up to 550 mm

-

Mass of recovered metal up to 60 kg

-

Powerful permanent magnetic system

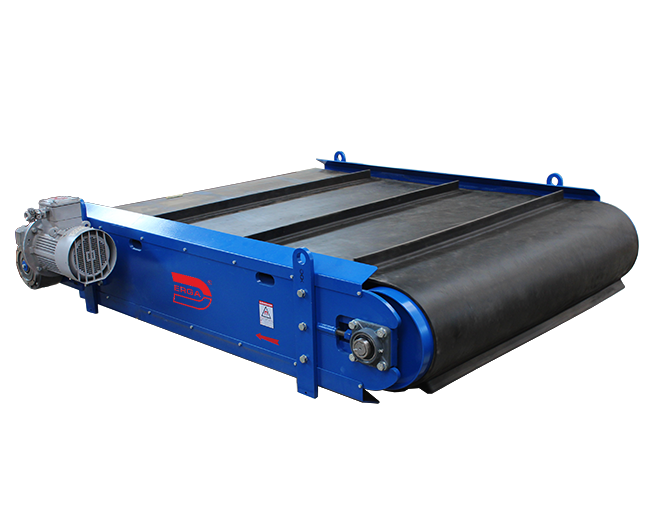

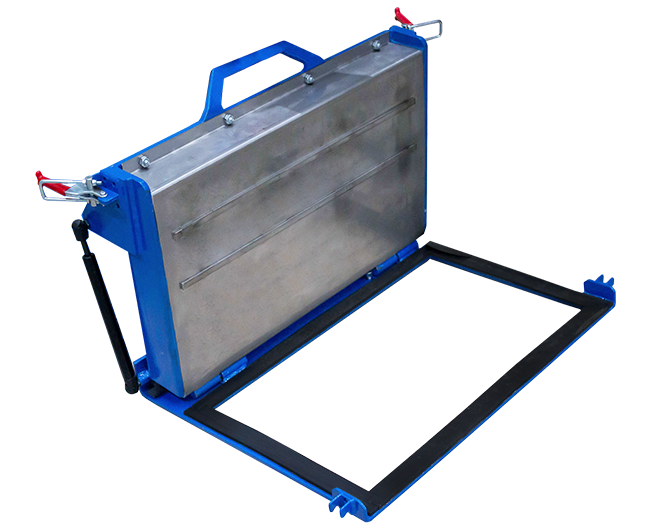

Overbelt magnetic separator ERGA SuspendMag М

-

Efficient recovery of large strongly magnetic impurities

-

Removal area depth up to 450 mm

-

Mass of recovered metal up to 40 kg

-

Easy assembly and operation

Overbelt self-cleaning magnetic separator for MSW ERGA SuspendMag A

-

Increased length of permanent magnetic system

-

Efficient throw of magnetic fraction outside conveyor

-

Removal area depth up to 350 mm

-

Mass of recovered metal up to 30 kg

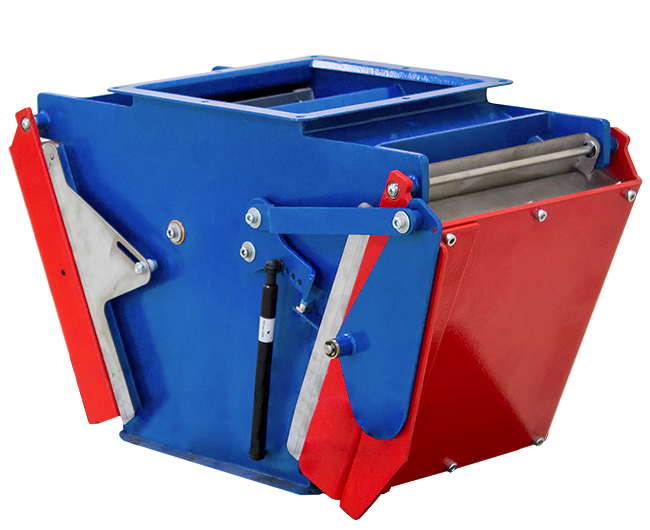

Eddy current magnetic separator for MSW sorting ERGA EddyFlow VF

-

Recovery of nonferrous metal particles from 2 mm

-

Highly efficient NdFeB magnetic system

-

User-friendly and fast setup

-

Material feed via a vibrating feeder

Magnetic drum separator ERGA DrumMag

-

Permanent magnetic system with induction from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 300 mm to 0.02 mm

-

Automatic cleaning

-

Operation temperature range from -50°С to +50°С

Automatic magnetic plate separator ERGA PlateMag A

-

Production automation

-

Highly efficient magnetic system with magnetic induction up to 0.9 T (9 000 Gauss)

-

Product cleaning efficiency up to 99%

-

Reliable retention of fines

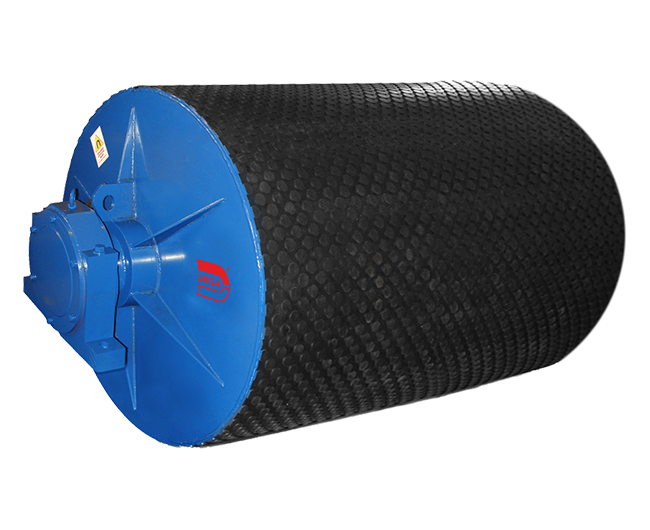

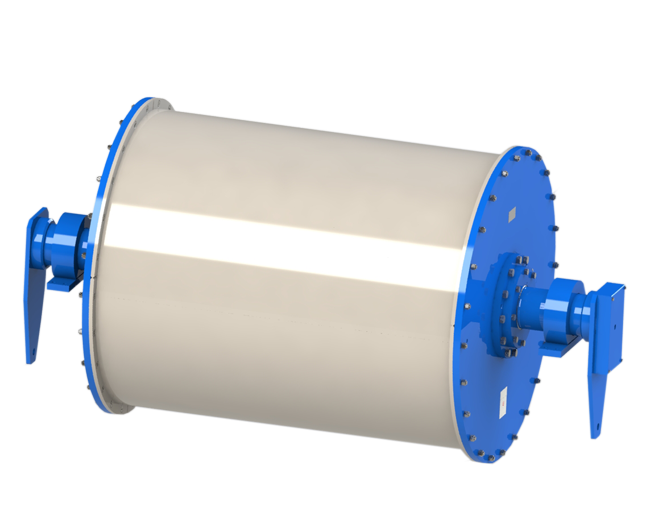

Magnetic pulley ERGA PullMag

-

2 in 1: magnetic iron separator + head pulley

-

Magnetic field operation range up to 350 mm

-

No power consumption

-

Automatic cleaning

Magnetic roll separator ERGA RollMag

-

High quality separation of weakly magnetic minerals

-

Highly efficient NdFeB magnetic system

-

Easy assembly and operation

-

Operating temperatures up to +180°С

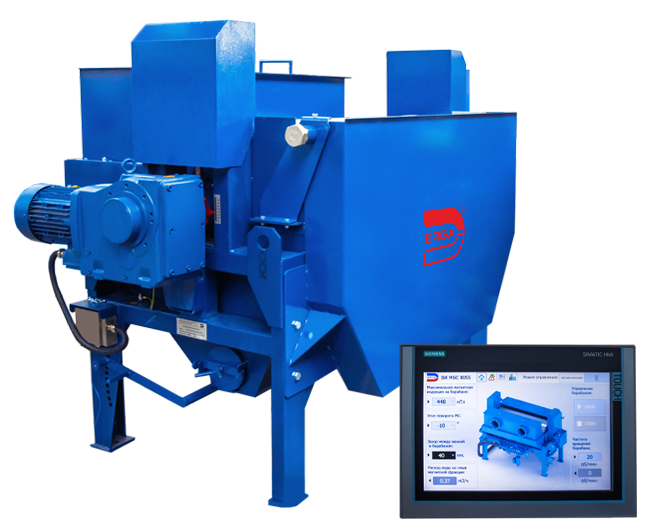

Eddy current magnetic separator with digital control ERGA EddyFlow E5

-

Recovery of metal particles from 3 mm

-

Separation/cleaning efficiency up to 99,8%

-

Highly efficient NdFeB magnetic system

-

Touch Screen intuitive control

Magnetic plate separator ERGA PlateMag 3

-

Off-the-shelf solution: iron separator + elevator boot

-

Highly efficient NdFeB magnetic system

-

Reliable retention of fines

-

Guarantee of end product quality

Magnetic drum separator ERGA DrumMag M

-

Permanent magnetic system with induction from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 150 mm to 0.02 mm

-

Dust protection

-

Availability of all settings necessary for operation

Eddy current magnetic separators ERGA EddyFlow and EddyFlow E

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal particles from 3 mm

-

User-friendly and fast setup

-

Highly efficient NdFeB magnetic system

Magnetic plate separator ERGA PlateMag 2

-

Integrated solution

-

Compact design of the housing

-

Highly efficient NdFeB magnetic system

-

High capacity of cleaning material

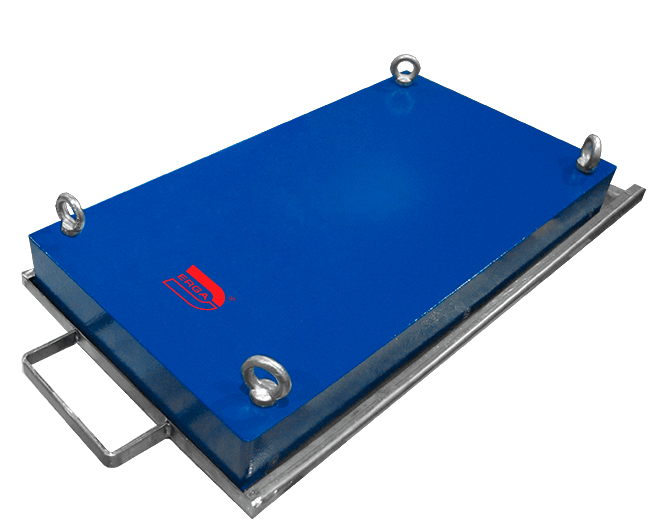

Overbelt magnetic separator ERGA SuspendMag P

-

Optimum solution for simple tasks

-

Removal area depth up to 200 mm

-

Easy assembly and operation

-

Easy cleaning

Magnetic double-drum separator for dusty products ERGA DrumMag DM

-

Minimum losses of fines during separation

-

Pure magnetic fraction

-

Dry separation method

-

Automatic cleaning

Wet magnetic drum separator ERGA WetMag

-

Permanent magnetic system with induction from 0.08 to 0.4 Т

-

Special magnetic system for wet separation process

-

Efficient recovery of magnetic inclusions with size from 0.005 mm to 10 mm

-

Protection of operating surfaces

Magnetic plate separator ERGA PlateMag

-

Integrated solution

-

Highly efficient NdFeB magnetic system

-

Reliable retention of fines

-

Guarantee of end product quality

Wet magnetic drum separator ERGA WetMag R

-

Reduction in expenses for dense-medium solids (magnetite, ferrosilicon)

-

Permanent magnetic system

-

Special design for efficient recovery

-

Customized selection of equipment

Magnetic plate separator ERGA PlateMag V

-

Integrated solution

-

Rugged design of casing for pressurized operation

-

Special NdFeB magnetic system

-

High capacity of cleaning material

Wet magnetic drum separator ERGA WetMag HI with automated control system

-

Automated adjustment of the permanent magnet system and operation modes

-

Automatic adaptation of separator settings

-

Extremely powerful magnetic system with adjustable induction from 0.1 to 0.6 T

-

Individual selection of magnetic drum size

Wet magnetic drum separator ERGA WetMag HI

-

Extremely powerful magnetic system with induction from 0.3 to 0.6 T

-

Individual selection of magnetic drum size

-

Special magnetic system for wet separation process

-

Wet separation method

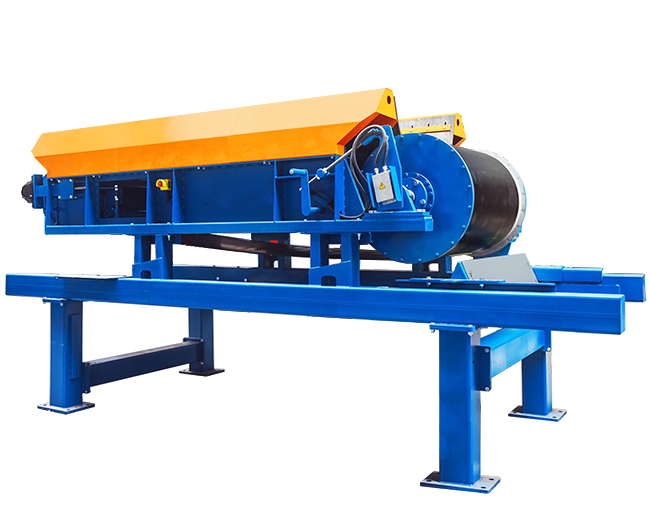

Conveyor magnetic separator ERGA PullMag C

-

Integrated solution

-

Powerful permanent magnetic system

-

Recovery of inclusions with size up to 350 mm

-

High energy efficiency

Conveyor magnetic separator ERGA DrumMag C

-

Integrated solution

-

Powerful permanent magnetic system

-

Recovery of magnetic inclusions size up to 300 mm

-

Sectoral magnetic system

Magnetic drum separator ERGA DrumMag IC

-

2 in 1: magnetic iron separator + drive pulley

-

Powerful permanent magnetic system

-

Recovery of magnetic inclusions size up to 300 mm

-

Sectoral magnetic system

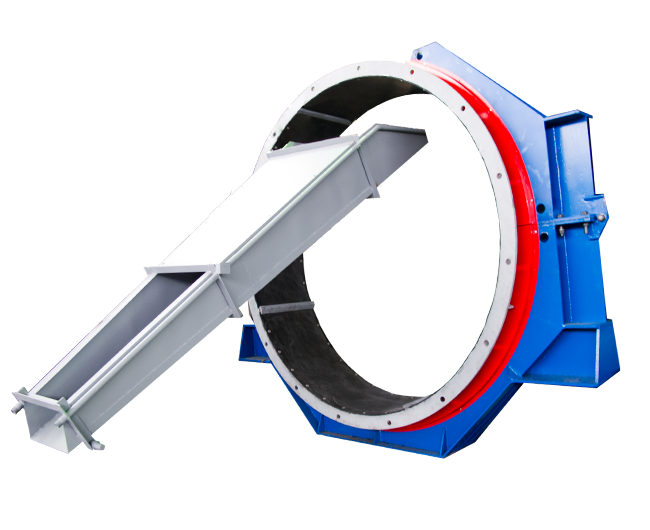

Scrap trap trunnion magnet ERGA TrunMag

-

Continuous diagnostics and automatic protection system

-

Improvement of ore dressing process

-

Customized solution for various mill sizes

-

Easy installation and operation

Magnetic separator is a device for cleaning raw materials in the industry, capturing metallic impurities, improving the quality and value of products. The separator protects equipment from the abrasive effects of iron particles, extending its service life. The principle of operation is based on the attraction of metals to a magnetic field and effectively separates contaminants from the product. The separator can be used to improve production efficiency, increasing the yield of the final product. It is indispensable in the recycling of metal slag or in food production.

ERGA manufactures complete sets and custom-designs magnetic separators for different business areas. Our magnetic separators can be used in food production, waste sorting, and slag recycling in the smelting or mining of ferrous and non-ferrous metals. Our engineers are ready to offer an off-the-shelf solution or design a system to meet your production or business needs. We are proud of our accumulated experience and help our partners gain profit while respecting the environment.

Our product range includes separators such as:

- Suspended magnetic separators

- Magnetic pulleys

- Magnetic plate separators

- Magnetic drum separators

- Magnetic roll separators

- Eddy current separators

Drum separators

Distinguished by a rotating drum through which the raw material passes. Widely used in ore processing, construction and other industries. Operate by attracting particles to the drum and releasing them into a collection hopper, as well as self-cleaning systems to maintain continuous operation. Advantages of our drum separators:

- permanent magnet based system with magnetic induction,

- wet separation,

- recovery of inclusions from 0.005 mm to 10 mm,

- operation at temperatures from -50°C +50°C,

- handling of abrasive materials.

Suspended magnetic separators

Used in industries where it is necessary to remove metallic impurities from raw materials or finished products. Suspended separators provide automatic separation of magnetic and non-magnetic materials, which improves the quality of the final product, protects equipment from damage and improves process safety. Advantages of our suspended separators:

- Extraction depth from 200 to 550 mm,

- Extracted metal weight up to 60 kg,

- Permanent magnet operation,

- Automatic cleaning,

- No power consumption.

Magnetic plate separators

They are used in work with bulk materials: grain processing, plastic processing, cement and others. The design includes magnetic plates made of powerful magnets, housing and chutes for the passage of the material, and adjustable configurations to adapt to the characteristics of the production line. The principle of operation is based on magnetic attraction and repulsion, allowing effective separation of ferromagnetic particles from the material. Plate separators are characterized by high product purification and reliability.

Advantages of our plate separators:

- Induction magnetic system,

- Product cleaning efficiency up to 99%,

- Automatic cleaning,

- Quality assurance of the final product.

We can design a full cycle of purification of raw materials or finished products using our in-house development. Our magnetic separators can extract 99% of impurities and operate with zero energy consumption. We guarantee the quality of the final product.