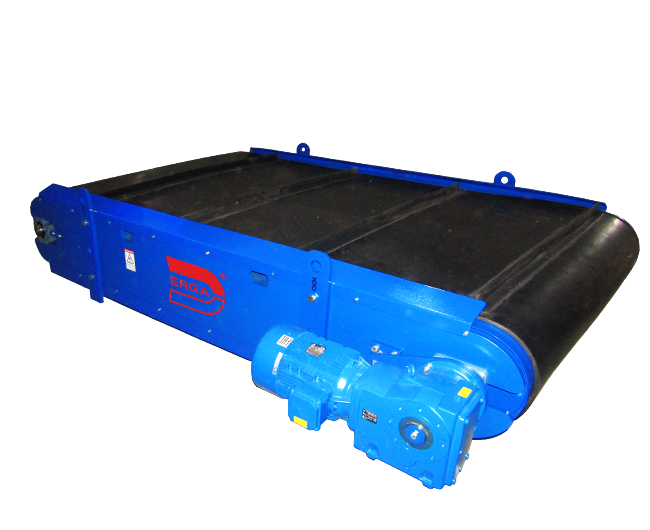

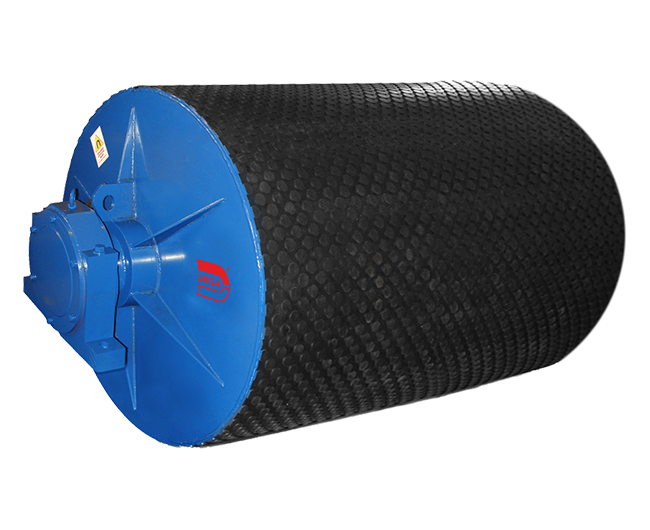

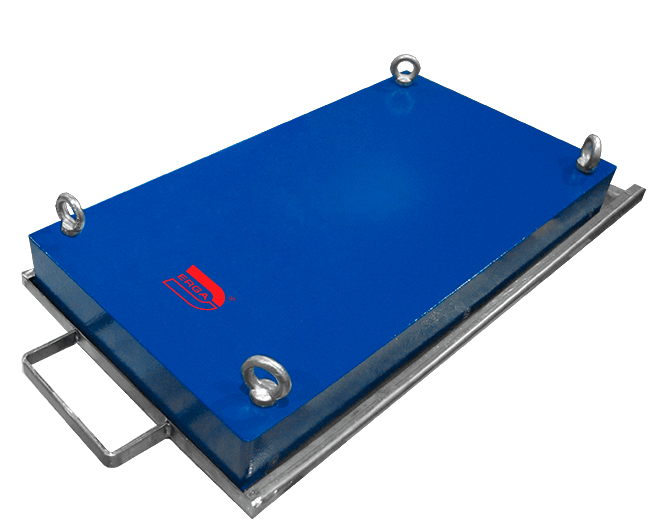

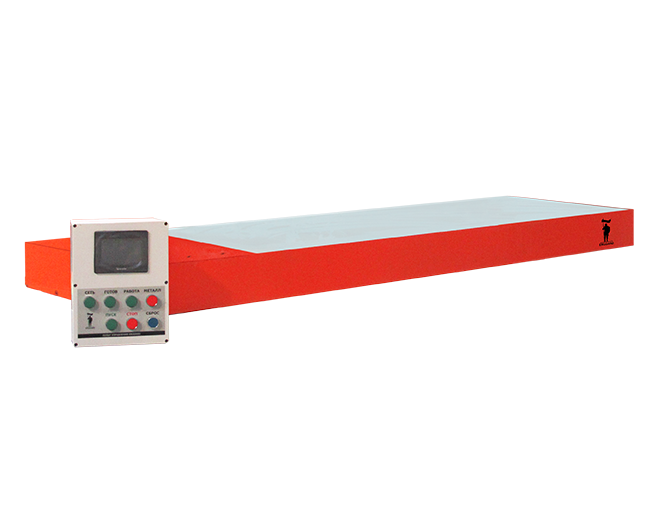

Overbelt self-cleaning magnetic separator ERGA SuspendMag A

Overband self-cleaning magnetic separator for removal of large strongly magnetic inclusions from material flows transported by belt conveyors

-

Efficient operation in harsh conditions

-

Removal area depth up to 550 mm

-

Mass of recovered metal up to 60 kg

-

Powerful permanent magnetic system

-

Automatic cleaning

-

Reliable components from the world leaders (Germany, Japan)

-

Minimum spare parts kit

-

Operating temperature range from -40°С to +60°С

-

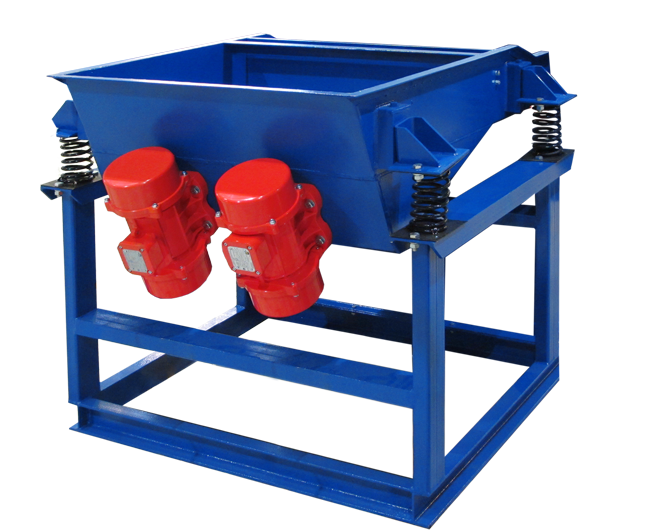

Protection of crusher, shredder from damage and early wear

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

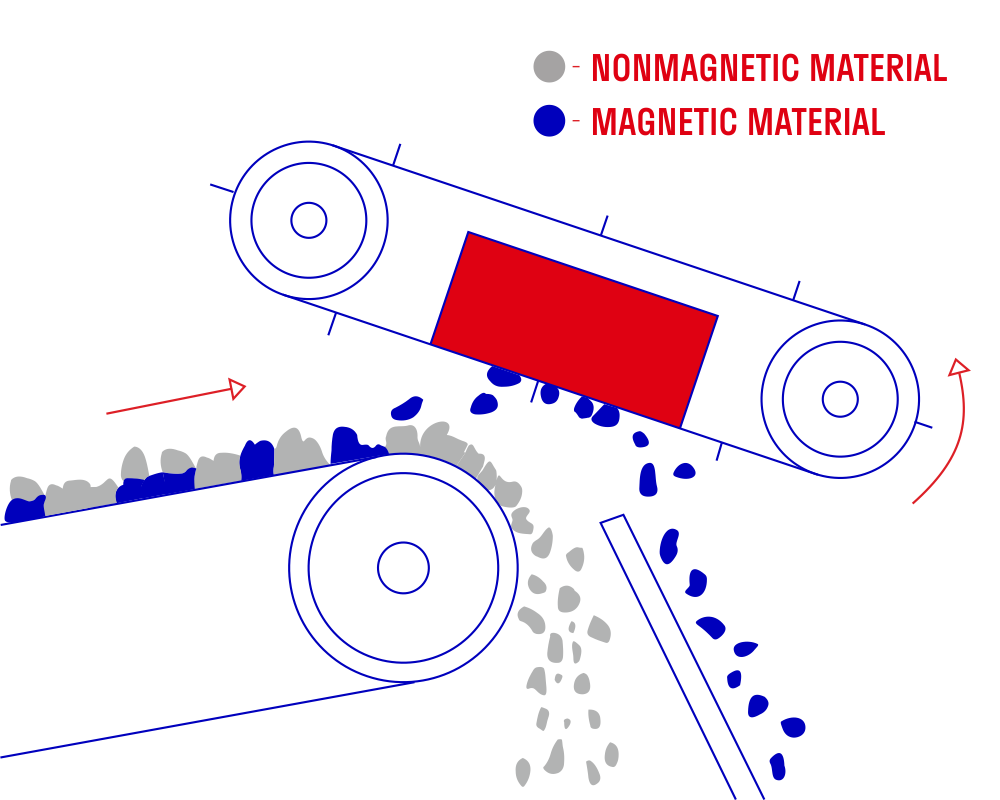

Operation Principle

Industries

Suspended magnetic separator with automatic cleaning ensure quality removal of large strongly magnetic inclusions with mass up to 60 kg from material flows from distance up to 550 mm.

- Efficient operation in harsh conditions

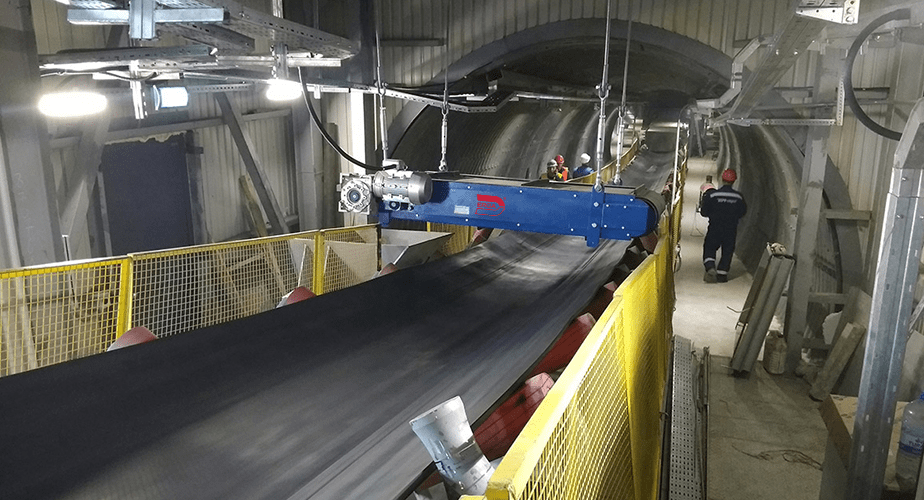

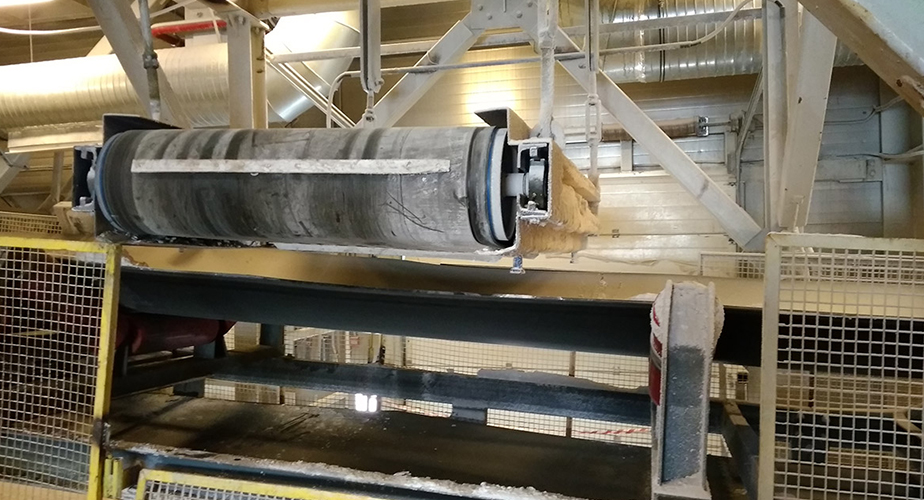

Overbelt self-cleaning magnetic separator ERGA SuspendMag A is designed for operation in extremely harsh conditions: powerful permanent magnetic system can remove extremely large metal inclusions with mass up to 60 kg, providing efficient cleaning even at high feed rate (up to 3.5 m/s).

- Protection of crusher, shredder from damage and early wear

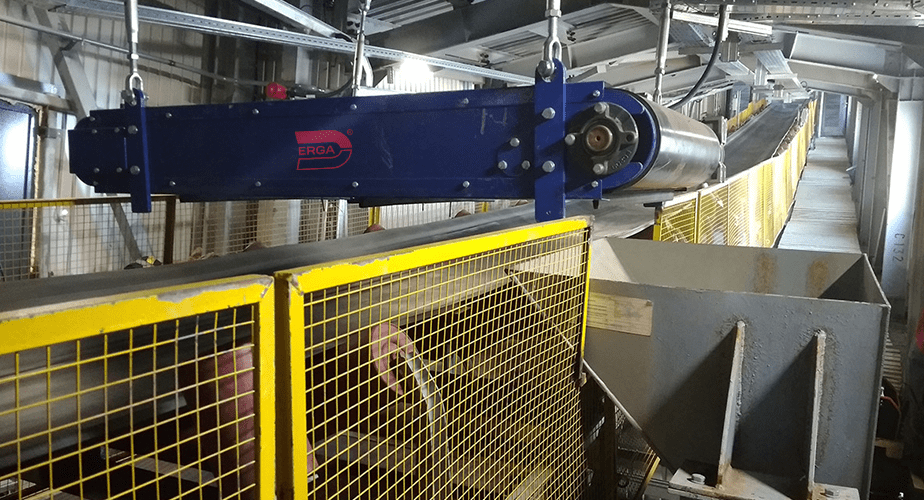

The magnetic separator for conveyor belts is installed above conveyor or at discharge from the conveyor belt. Applied as a component of process lines, ERGA SuspendMag A prevents damage to expensive equipment with all the resulting financial losses.

- Automatic cleaning

Continuous cleaning from magnetic impurities is automatic and does not involve any personnel intervention.

- Conformity with industrial safety regulations

The equipment correspond to the requirements of industrial safety regulations and rules valid and can be applied at explosive and flammable chemically hazardous enterprises and facilities, including mines with explosive proof, coal dust and methane access. All required certificates are included in the scope of supply.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.