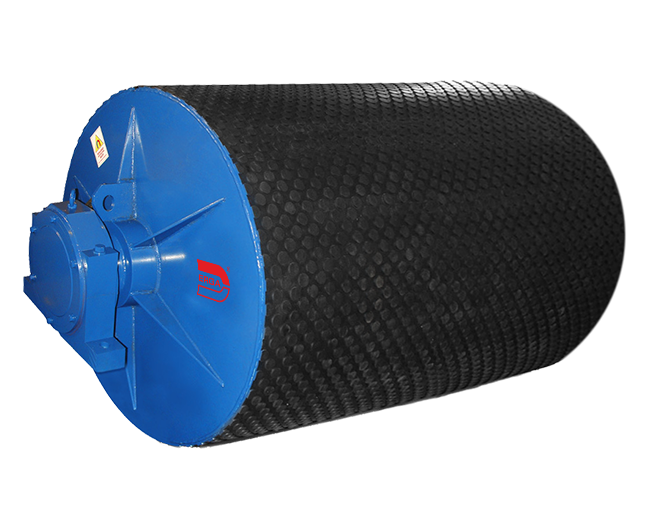

Magnetic pulley ERGA PullMag

Belt conveyor head pulley with powerful magnetic systems for removal of large strongly magnetic inclusions from deep layers of bulk materials

-

2 in 1: magnetic iron separator + head pulley

-

Magnetic field operation range up to 350 mm

-

No power consumption

-

Automatic cleaning

-

Permanent magnetic system with maximum operating range

-

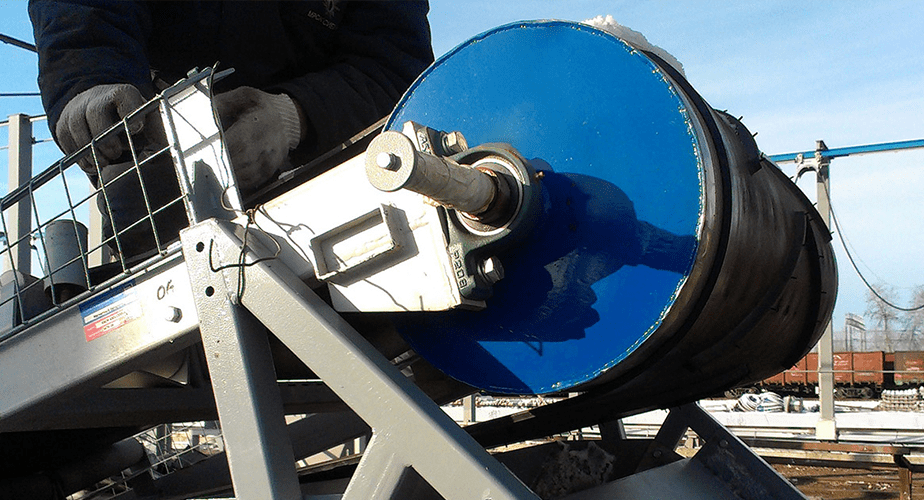

Easy assembly and operation

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

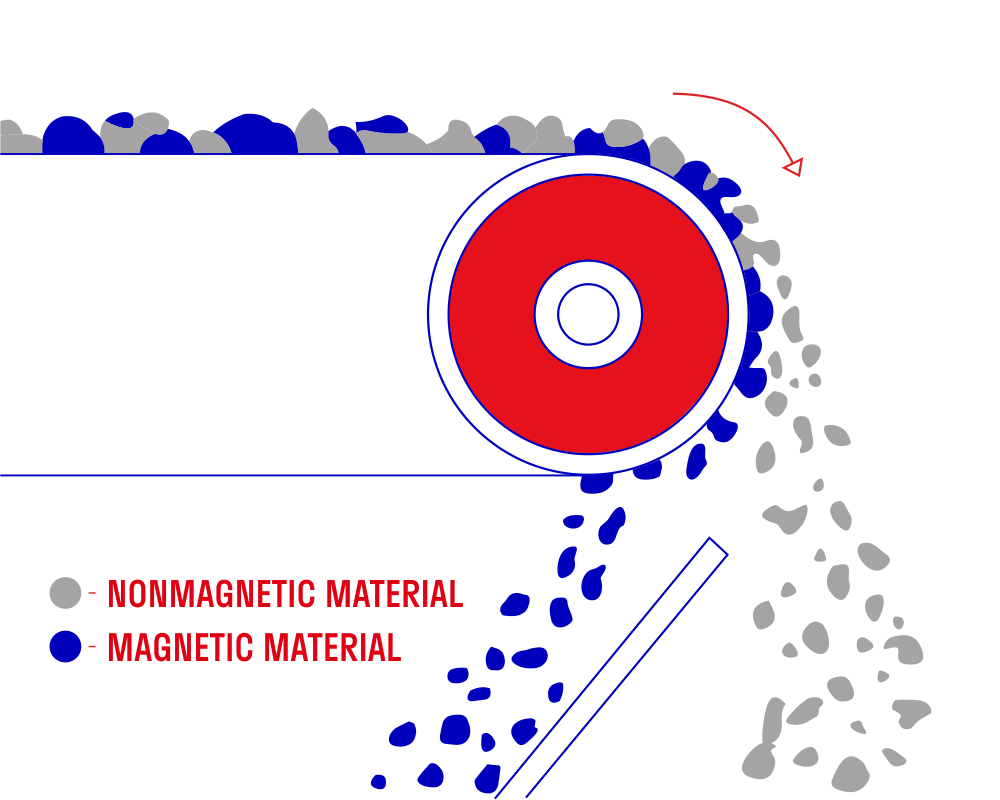

Operation Principle

Industries

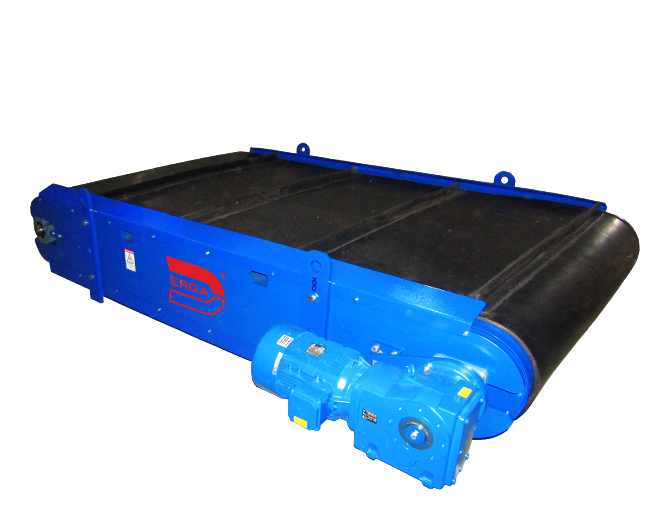

Magnetic pulley ERGA PullMag iron separator with automatic cleaning provides quality removal of strongly magnetic inclusions of various sizes from deep layers of bulk materials.

- 2 in 1: magnetic iron separator + head pulley

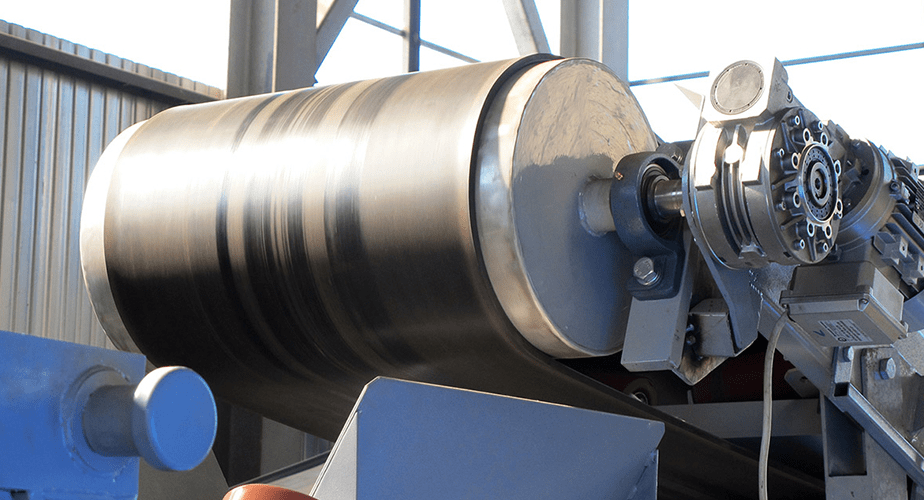

ERGA PullMag is integrated into conveyor as a head pulley at the place of material discharge from the belt, providing continuous cleaning of raw materials from impurities. IMPORTANT: additional lining of the pulley prevents the belt slippage and minimizes its wear.

- Magnetic field operation range up to 350 mm

Robust design is represented by the permanent magnet system built-in the drum rotating on bearing supports. Powerful permanent magnetic system provides high operation range (up to 350 mm) with magnetization of the whole operating zone and guarantees metal recovery from deep layers of material.

- No power consumption

The equipment does not consume any electric power for magnetic field generation and differs from electromagnetic analogs in significantly greater reliability. The guaranteed shelf life of the magnetic system properties, subject to operating rules, is 10 years.

- Automatic cleaning

Continuous cleaning from magnetic impurities is automatic and does not involve any personnel intervention.

- Conformity with industrial safety regulations

The equipment correspond to the requirements of industrial safety regulations and rules valid and can be applied at explosive and flammable (including vegetable stock storage, processing and application facilities, chemically hazardous enterprises and facilities, including mines with explosive proof, coal dust and methane access. All required certificates are included in the scope of supply.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

ERGA magnetic iron separators are designed and custom-made according to the order requirements of the Customer.

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- lining

- bearings

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor