Scrap trap trunnion magnet ERGA TrunMag

Permanent magnetic system for continuous extraction of strongly magnetic scrap, chips, balls and fragments from the pulp

-

Continuous diagnostics and automatic protection system

-

Improvement of ore dressing process

-

Customized solution for various mill sizes

-

Easy installation and operation

-

No power consumption

-

Additional lining

-

Energy efficiency increase

-

Automatic cleaning

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

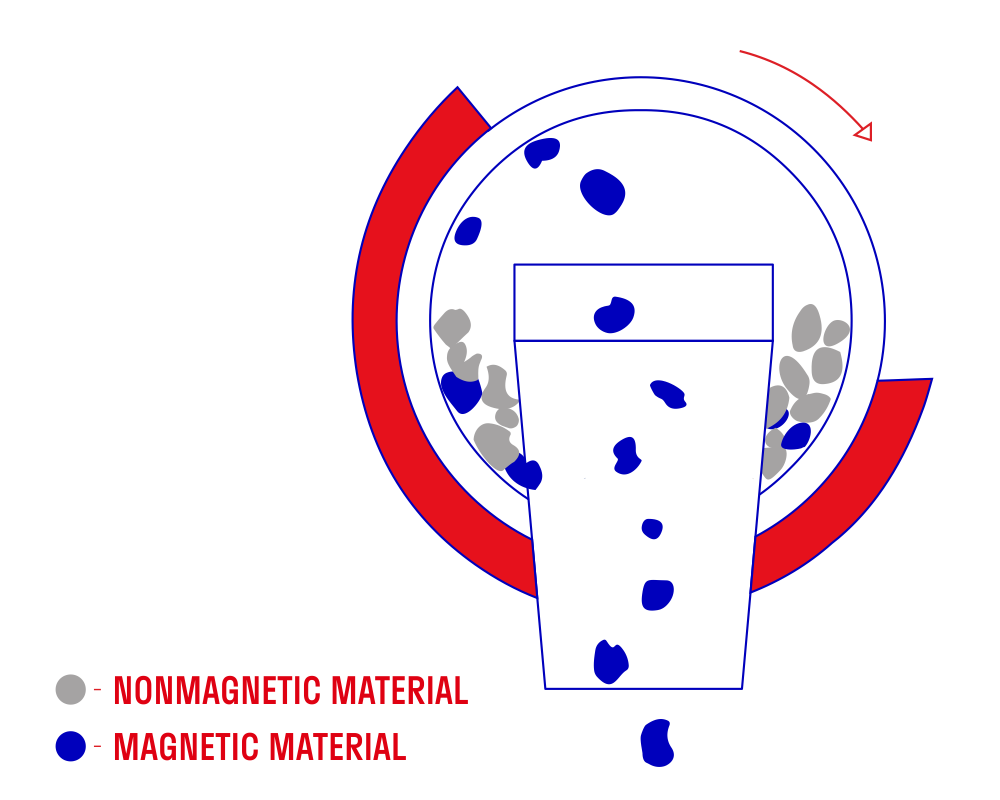

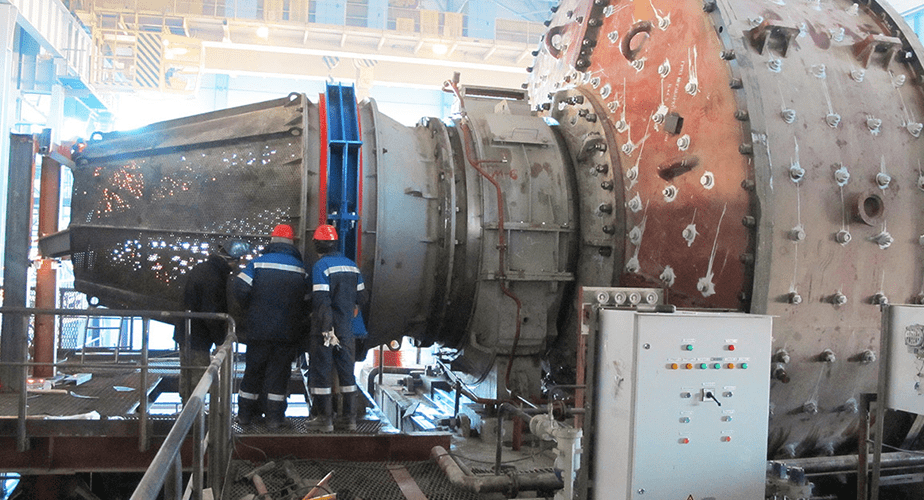

ERGA TrunMag magnetic system provides continuous and automatic removal of grinding ball fragments from the ground products of ball, rod and SAG mills.

- Protection of expensive equipment from damage and premature wear

Powerful permanent magnet system (sector with 2000 angle) removes and discharges grinding ball fragments into the discharge zone, preventing wear and damage of the transportation, classification and pumping equipment caused by the presence of metal parts and fragments in the product. The iron scrap removal from the milling cycle with TrunMag magnetic separation plants allows for 2-4 times reduction of wear rate of transportation systems, pump, classifying and other equipment, accordingly reducing maintenance and repair costs.

- Improvement of ore dressing process

When metal scrap gets into the process, ore dressing values at the stage of rough concentrate separation decrease. Removing scrap from the technological process in gold ore processing increases the yield of rough concentrate by 1.5% and recovery of gold in rough gravity concentrate by 9.2% from the operation.

- Customized solution for various mill sizes

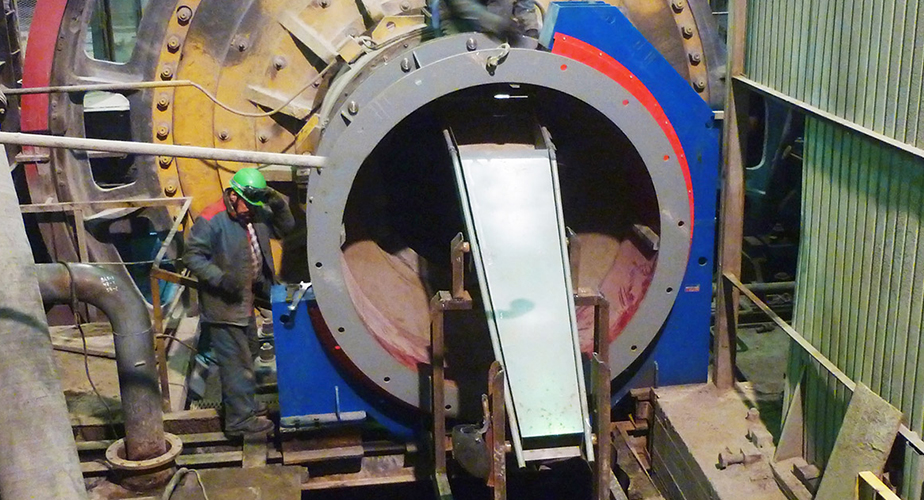

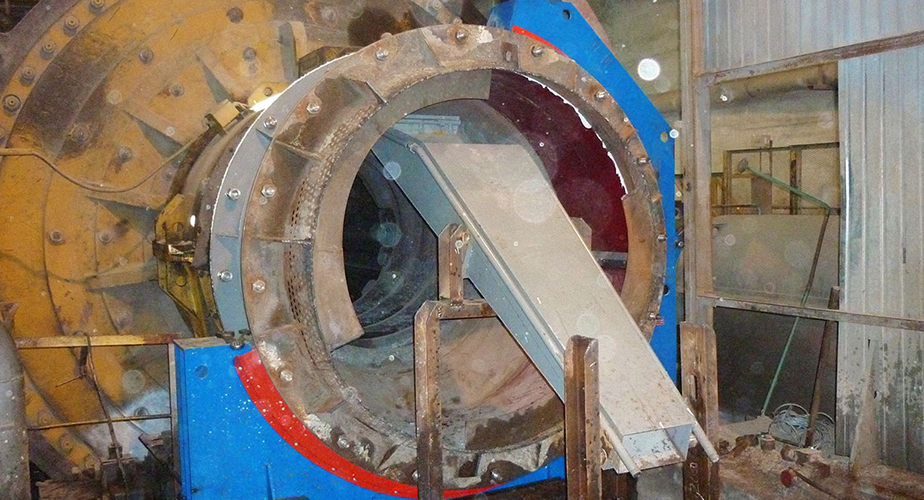

Many years of manufacturing experience allow ERGA to provide custom solutions of the problem: design and produce trunnion magnets for specific mill sizes, taking into account their mounting dimensions.

- Easy installation and operation

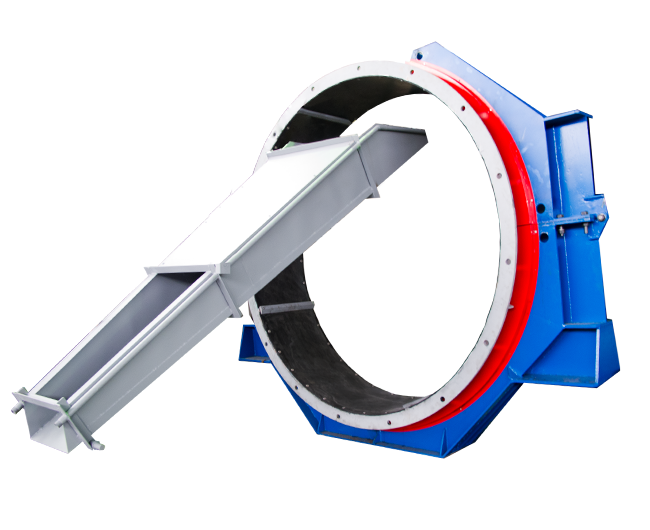

The magnetic system drum is mounted on the discharge flange of the balling drum. The drum is designed for mounting trammel and has the same mounting dimensions, minimum size and represents a space ring. The magnetic sector is mounted on its own supports and requires preparation of the site for its installation. The discharge tray is mounted in cantilever on the supporting structure, provides continuous removal of the scrap outside the operating area.

The trunnion magnet operates without operator intervention and does not require any special maintenance.

- Automatic cleaning

Continuous recovery of raw materials from magnetic impurities is automatic without personnel involvement.

Continuous separation and removal of magnetic impurities in automatic mode significantly improves process quality.

- No power consumption and increase in energy efficiency

TrunMag magnetic scrap trap does not require power for magnetic field generation. The guaranteed operation life of magnetic systems, subject to operating rules, is 10 years. High-quality removal of worn grinding balls reduces power consumption of crushing equipment up to 8% due to the elimination of operation with excessive load.

- Additional lining of magnetic system

Operating surfaces of the magnetic system are protected against accelerated wear with polyurethane lining.

Removable lining significantly increases operating life of the trunnion magnet surfaces.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

ERGA TrunMag magnets are engineered and manufactured considering mounting dimensions and model of the customer’s mill.

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- lining

- splitters

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the UMS status in real time. Available options:

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor