Magnetic roll separator ERGA RollMag

ERGA RollMag high intensity magnetic separator for dry mineral processing and high-quality cleaning of materials from weakly magnetic particles

-

High quality separation of weakly magnetic minerals

-

Highly efficient NdFeB magnetic system

-

Easy assembly and operation

-

Operating temperatures up to +180°С

-

Automatic cleaning

-

Production automation

-

Robust proven design

-

Dry separation method

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

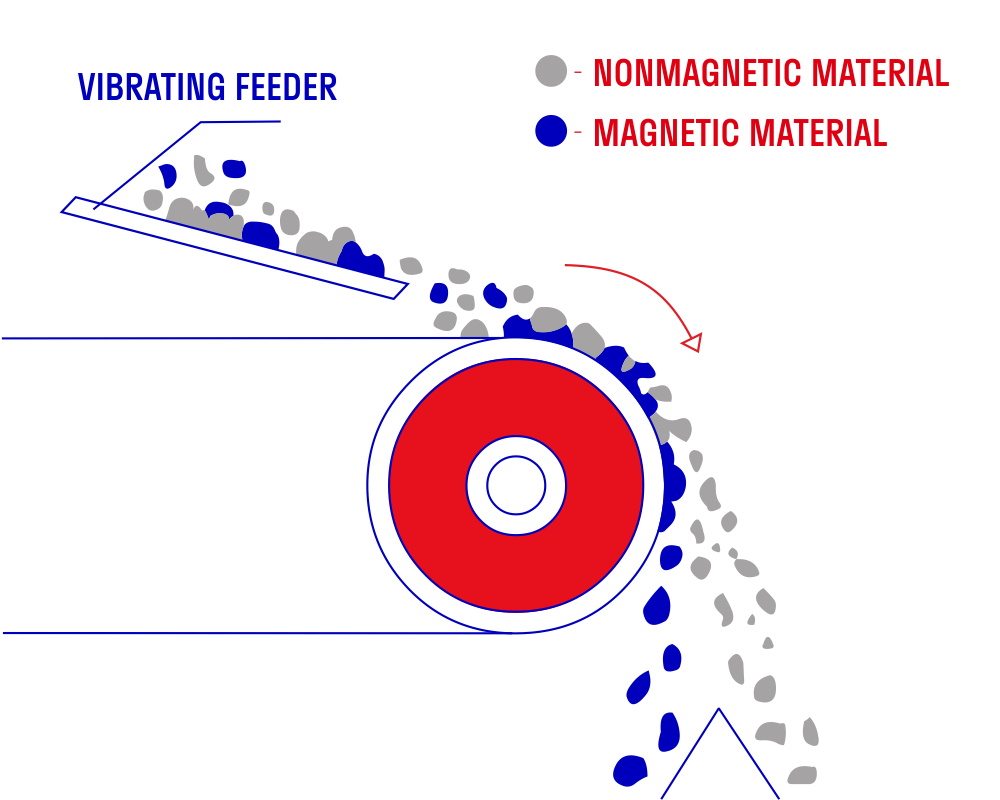

High intensity magnetic separators ERGA RollMag provide dry mineral processing and high-quality cleaning of materials from weakly magnetic particles.

- High quality separation

Individually selected RollMag 1, 2, 3 models for one-, two- or three-stage separation with corresponding number of magnetic rolls guarantee high-quality processing of both nonmagnetic (quartz sands, feldspar, kaolin raw materials, semolina, etc.), and magnetic (titanium zirconium sand, chromite ore, manganese ores, etc.) materials.

- Highly efficient NdFeB magnetic system

Unique patented magnetic system provides increased magnetic intensity on the operating surface up to 2 T (20300 G) without power consumption for magnetic field generation, unlike electromagnetic analogs.

- Easy assembly and operation

The control systems in magnetic separators of RollMag 1, 2, 3 series are optimized for easy setting of equipment operating modes. ERGA RollMag can be connected to aspiration systems for dust removal. Special thin Kevlar belts with self-tensioning and alignment system can be quickly installed or replaced in just 5 minutes.

- Operating temperatures up to +180°С

Application of special NdFeB alloys and high-temperature materials in RollMag separator construction parts provide efficient operation at product temperatures up to +180°С.

- Automatic cleaning

Cleaning of raw materials from weakly magnetic impurities is automatic without personnel involvement. Continuous removal of magnetic inclusions in automatic mode improves separation quality.

- Dry separation method: pure economy!

High intensity separators ERGA RollMag allow for replacement or supplement existing equipment, improving the quality of material separation with less power consumption and no time and money spent on water and drying**.

** comparing to wet separation method

- Robust design -guaranteed result!

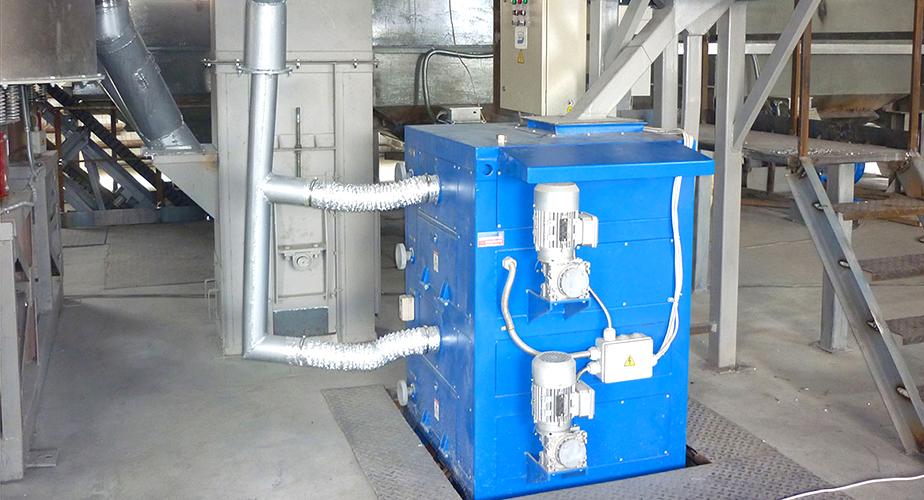

The robust design of high intensity roll separators ERGA RollMag, proven by the experience of numerous installations in various industries, is compact in comparison with electromagnetic analogs and has convenient and easily accessible adjustment of the separation process.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced models of RollMag separators are given in the table. It is recommended to use DrumMag M series drum magnetic separators to remove strongly magnetic component of the material before it is fed to roll separators of RollMag series. Customized solutions can be designed according to the order requirements.

| Model | Dimensions, mm | Power consumption, kW | Capacityt/h* | Magnetic rolls, qty | Weight, kg |

|---|---|---|---|---|---|

| RollMag 1M 400 | 1170х930х875 | 0,6 | 1 | 1 | 350 |

| RollMag 2M 400 | 1250х930х1510 | 1,7 | 2 | 2 | 600 |

| RollMag 2M 800 | 1650х930х1510 | 1,7 | 5 | 2 | 800 |

| RollMag 2M 1200 | 2050х930х1510 | 3,5 | 8 | 2 | 950 |

| RollMag 2M 1500 | 2350х930х1510 | 3,5 | 10 | 2 | 1200 |

| RollMag 3M 1500 | 2350х1050х2110 | 5,5 | 10 | 3 | 2200 |

* Average capacity values are given and it will depend on size and density of the separated material

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- belts

- bearings

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor