Magnetic drum separator ERGA DrumMag M

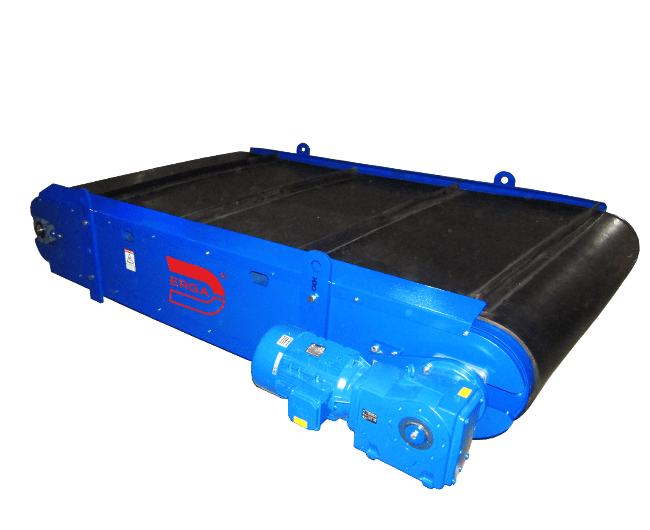

Automatic magnetic separator for continuous recovery of tramp metal of various sizes from dry bulk material

-

Permanent magnetic system with induction from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 150 mm to 0.02 mm

-

Dust protection

-

Availability of all settings necessary for operation

-

Option of 2 separation stages in one housing

-

Automatic cleaning

-

Operation temperature range from -50°С to +50°С

-

Operation with abrasive materials

-

Easy installation and operation

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

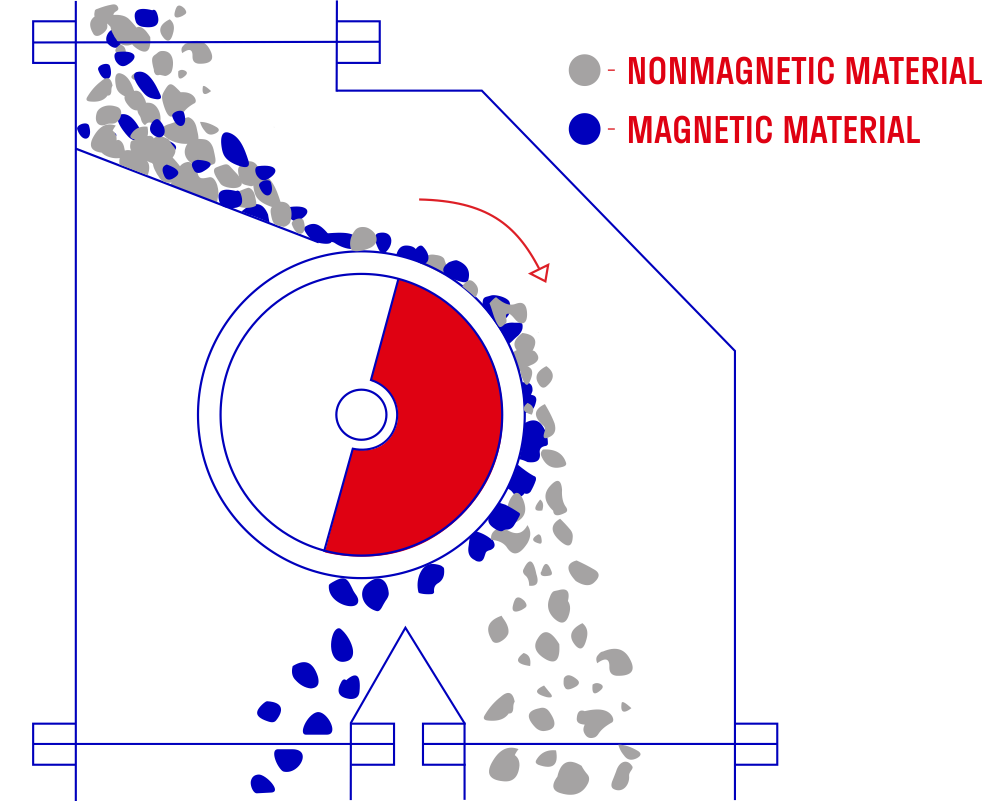

Operation Principle

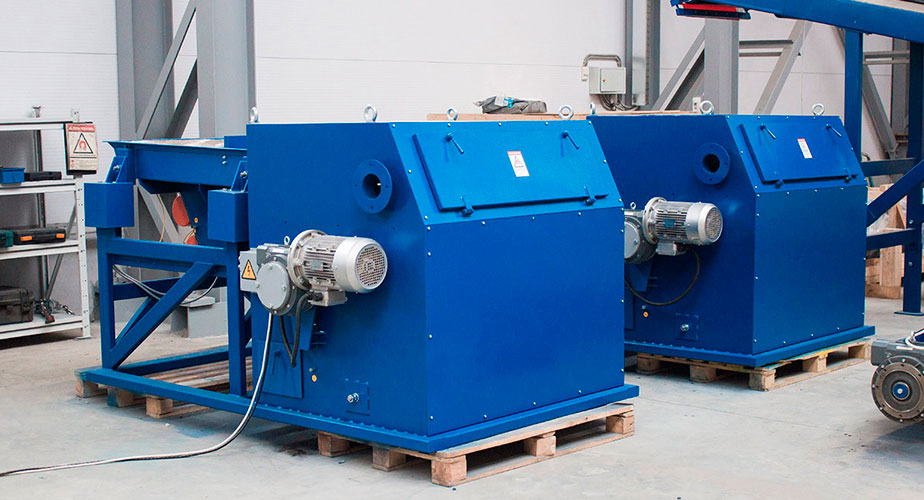

Self-discharging ERGA DrumMag M magnetic drum separator differs from ERGA DrumMag separator in its housing with a feed head, adjustment systems for magnetic system, feeding and splitter. Recleaning of magnetic or nonmagnetic fraction is possible with installation of the second additional drum.

- Efficient recovery of magnetic inclusions with size from 150 mm to 0.02 mm

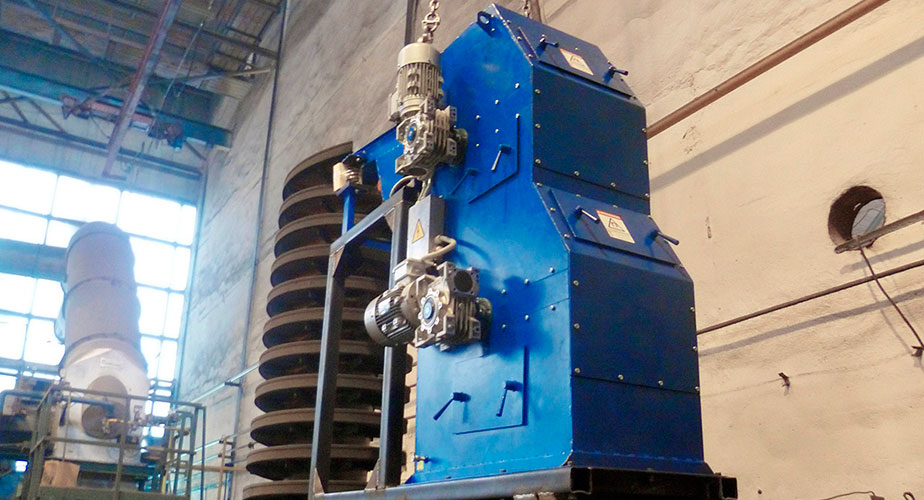

The separator design increases uniform distribution of material along the drum operating surface thanks to the feed head with a gate or vibrating feeder.

DrumMag M field induction value determines its efficiency for removal of metal inclusions:

- from 0.08 to 0.24 T (from 800 to 2 400 Gauss) for high-capacity (up to 350 t/ h) dry magnetic separation of crushed magnetite ores with resulting tailings with minimum content of magnetite iron provides a saleable product up to 150 mm from ferrous metal slag dumps. DrumMag M protects crusher and shredder from damage and premature wear;

- from 0.24 to 0.6 T (from 240 to 6,000 Gauss) for upgrading quality of raw materials by removal of small magnetic inclusions (metal rubbings, scale, etc.) with grain size up to 0.02 mm in processing of ores and nonmetallic materials with medium magnetic susceptibility (ferrous slags, iron, manganese, chromium and other ores);

- up to 1 T (up to 10 000 Gauss) for maximum cleaning of material from magnetic inclusions with size up to 0.02 mm, including weakly magnetic (manganese and stainless steels), thereby increasing the end product value. ERGA DrumMag M with this magnetic induction guarantees the production of high-quality material with minimum content of contaminants in processing of ores and nonmetallic materials with weak magnetic susceptibility (titanium-zirconium, calumbite-tantalite, oxidized and carbonate iron ores, etc.).

- Dust protection

The separator drum is enclosed in a dustproof housing to reduce dust emissions during operation of the separator with fine, dusty material. The separator housing can have dust collection pipes.

- Availability of all settings necessary for operation

DrumMag M is equipped with a full range of settings for efficient operation and solving customer’s problems in the best way. Fine adjustments of the splitter’s position, drum speed and magnetic system position guarantee high separation efficiency.

- Option of 2 separation stages in one housing

Option of two separation stages in one housing improves separation efficiency and equipment performance. The second magnetic drum can be installed for recleaning magnetic or non-magnetic fraction of the first separation stage.

- Automatic cleaning

Cleaning of raw materials from magnetic impurities is automatic without personnel involvement. Continuous removal of magnetic inclusions in automatic mode guarantees constant separation quality.

- Operation temperature range from -50°С to +50°С

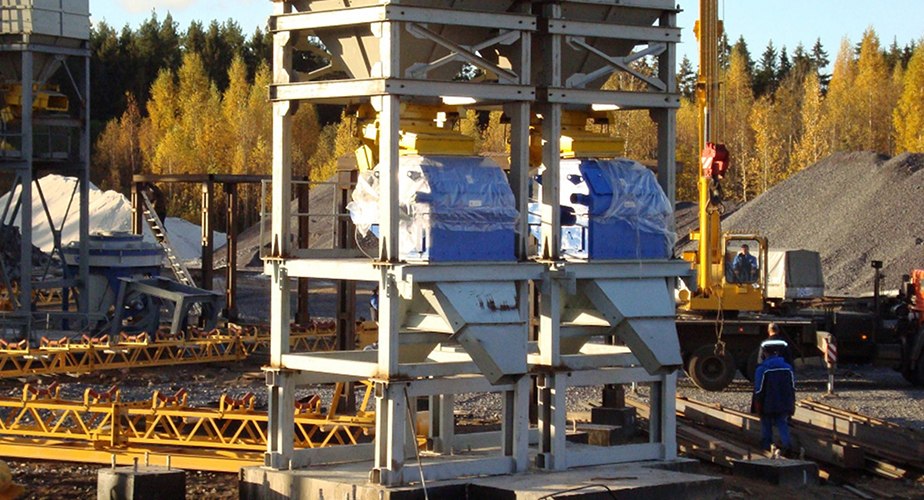

Reliable magnetic system and simple design of the separator ensure its operability in a wide temperature range from -50°С to +50°С. DrumMag M provides efficient operation in any weather conditions, indoors and outdoors.

- Operation with abrasive materials

The separator operating surface is made of durable abrasion-resistant chrome-nickel steel. In case of operation in highly abrasive medium, the separator shell is additionally lined with wear plates.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

ERGA product portfolio includes different models of DrumMag M self-discharging magnetic separators with operating zone width from 200 to 2 500 mm. Customized solutions can be designed according to the order requirements.

| Model | Dimensions, mm | Magnetic induction, mТ | Power consumption, kW | Capacity, m³/h | Mass, kg |

|---|---|---|---|---|---|

| DrumMag M 200х200 | 540х404х641 | 50-900 | 0,18 | 1,5 | 100 |

| DrumMag M 335х300 | 730х770х900 | 50-900 | 0,25 | 4 | 195 |

| DrumMag M 335х400 | 730х800х900 | 50-900 | 0,25 | 5 | 220 |

| DrumMag M 335х600 | 730х1000х900 | 50-900 | 0,5 | 7 | 300 |

| DrumMag M 335х800 | 730х1235х900 | 50-900 | 0,75 | 11 | 350 |

| DrumMag M 600х500 | 1160х1320х1300 | 50-900 | 2,2 | 10 | 900 |

| DrumMag M 600х1000 | 1160х1820х1300 | 50-900 | 3 | 25 | 1150 |

| DrumMag M 600х1500 | 1160х2350х1300 | 50-900 | 5,5 | 40 | 1400 |

| DrumMag M 900х1000 | 1500х2000х1600 | 50-900 | 5,5 | 40 | 1700 |

| DrumMag M 900х1500 | 1500х2500х1600 | 50-900 | 5,5 | 50 | 2000 |

| DrumMag M 900х2000 | 1500х3000х1600 | 50-900 | 7,5 | 75 | 2300 |

| DrumMag M 900х2500 | 2100х3650х2080 | 50-900 | 11 | 200 | 3600 |

* If necessary the products can be equipped with aspiration system, variable frequency drive, equipment status feedback sensor, temperature-controlled system to maintain the temperature mode on the magnetic system. Accessories can be supplied with the product as per customer’s requirements.

Products are delivered with all necessary certificates.

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- lining

- bearings

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor