Magnetic double-drum separator for dusty products ERGA DrumMag DM

Automatic magnetic separator for continuous recovery of metal inclusions from fine dusty material

-

Minimum losses of fines during separation

-

Pure magnetic fraction

-

Dry separation method

-

Automatic cleaning

-

Operation with abrasive materials

-

Sealed housing

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

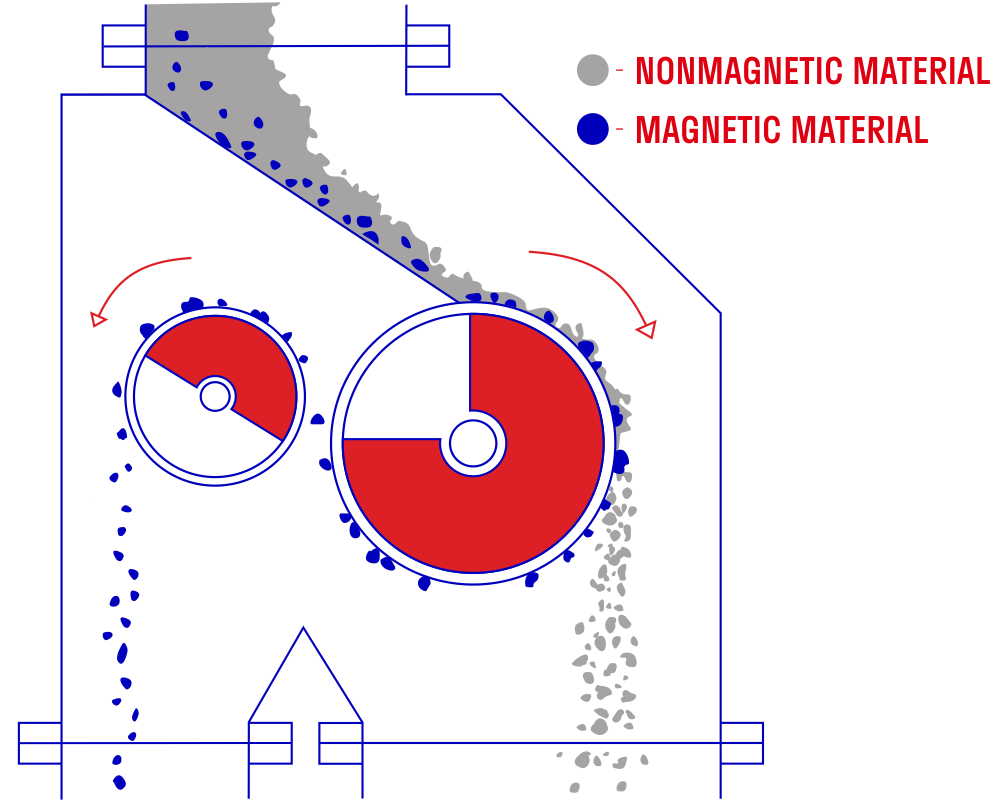

Operation Principle

Industries

Self-discharging ERGA DrumMag DM magnetic drum separator differs from DrumMag M type in installation of the special second drum for recovery of magnetic impurities from dusty material.

- Minimum losses of fines during separation

The separator is specially designed for difficult task of removing small magnetic impurities from dusty material in dry environment. Maximally isolated zones of separation and discharge of products help to minimize loss of valuable finely dispersed product.

- Pure magnetic fraction

Availability of the second auxiliary drum for recovery and transportation of magnetic inclusions to the discharge zone, as well as intense magnetic stirring, ensure high concentration of magnetic particles in the end product. ERGA DrumMag DM separator is used for processing nickel and iron slags, bottom ash and fly ash, crushed magnetite, iron and chrome ores, dedusting plant dust, dolomites, magnesites, expanded clay and other refractory materials at processing plants in glass, refractories and abrasive industries.

- Dry separation method

DrumMag DM double drum separator allows you to improve material quality with lower energy consumption without additional financial and time expenditures for water and drying.

- Automatic cleaning

Cleaning of raw materials from magnetic impurities is automatic without personnel involvement. Continuous removal of magnetic inclusions in automatic mode improves separation quality compared to separators with mechanical or manual cleaning.

- Operation with abrasive materials

The separator operating surface is made of durable abrasion-resistant chrome-nickel steel. In case of operation in highly abrasive medium, the separator shell is additionally lined with wear plates.

- Sealed housing

The sealed housing provides comfortable operation with dusty materials indoors without any harm to the operators’ health.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

ERGA product portfolio includes different models of DrumMag DM self-discharging magnetic separators with operating zone width from 300 to 1 000 mm. Customized solutions can be designed according to the requirements in technical specification.

| Model | Dimensions, mm | Magnetic induction, mТ | Power consumption, kW | Mass, kg |

|---|---|---|---|---|

| DrumMag DM 335х300 | 700х900х1000 | 450 | 2,6 | 350 |

| DrumMag DM 335х800 | 1200х900х1000 | 450 | 3 | 600 |

| DrumMag DM 415х1000 | 1500х1400х1200 | 450 | 5 | 900 |