Wet magnetic drum separator ERGA WetMag

Wet permanent magnetic separator for continuous concentration of ores and nonmetallic materials

-

Permanent magnetic system with induction from 0.08 to 0.4 Т

-

Special magnetic system for wet separation process

-

Efficient recovery of magnetic inclusions with size from 0.005 mm to 10 mm

-

Protection of operating surfaces

-

Wet separation method

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

Operation Principle

Industries

A self-discharging ERGA WetMag permanent magnetic drum separatoris specialized equipment designed to remove ferromagnetic materials from liquids, slurries and fine materials in the mineral processing process. Unlike dry magnetic separators that handle dry powders or granules, wet drum separators handle liquid or slurry-like materials. In the mining industry, wet separators play a key role in the recovery of magnetic minerals such as magnetite, ferrosilicon and others, helping to maximize the economic potential of ore deposits.

Permanent magnetic system

The magnetic field parameters are selected individually depending on magnetic susceptibility of concentrated material:

- for recovery of strongly magnetic concentrate (magnetite ore dressing, CHP plant ash, removal of industrial iron) the recommended magnetic induction in the operating area is 0.08-0.24 T;

- for getting tailings with minimum content of useful magnetic product or for recovery of less magnetic materials (oxidized industrial iron, ferromanganese minerals, etc.), the recommended induction in the operating area is 0.24-0.4 T.

Special magnetic system for wet separation process

Special magnetic system design is used for this type of equipment. The wet drum magnetic separators are deep magnetization of the operating zone for maximum recovery of magnetic particles and high-induction magnetic stirring for breaking magnetic floccules and receiving magnetic concentrate.

Efficient recovery of magnetic inclusions of various sizes

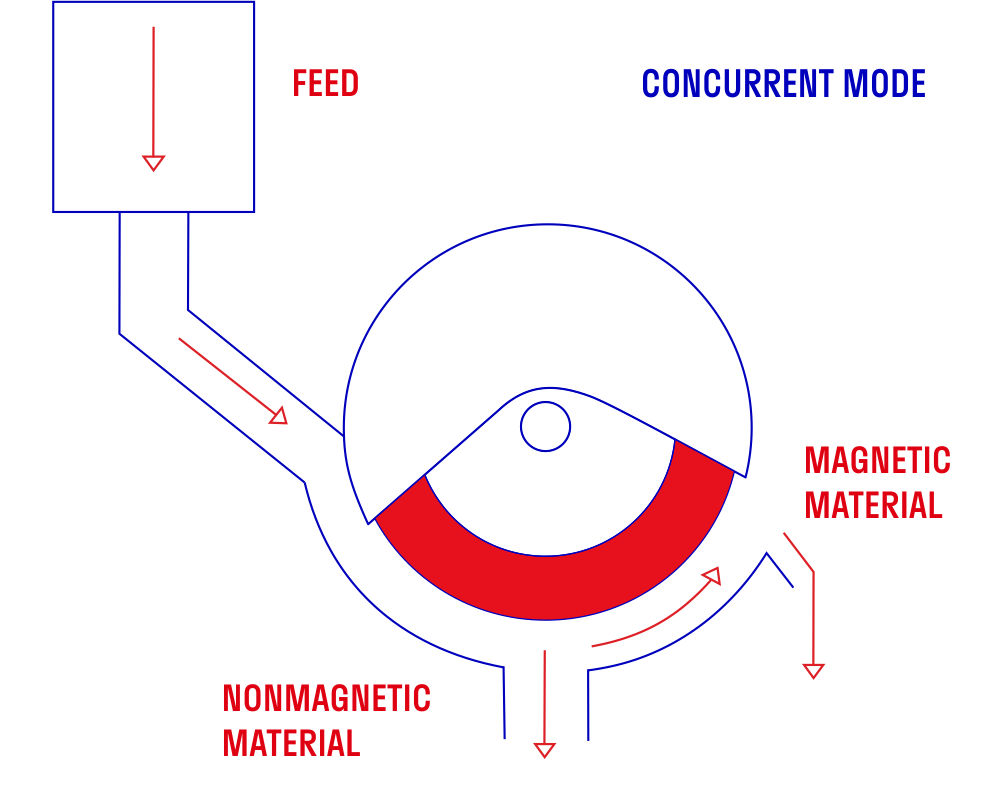

Efficient recovery of magnetic inclusions in separated fractions is achieved by customized selection of the required bath type:

- concurrent bath is used for coarse material (up to 10mm);

- countercurrent bath is for material size up to 3 mm;

- semi-countercurrent bath is for fine material (98% less than 0.071 mm).

Wet separation method

The wet separation process allows for processing of a wide range of particle sizes to produce high-quality saleable magnetic concentrate.

Protection of operating surfaces

Wear-prone separator parts (bath,drum) are lined with special wear-resistant coatings. Separator covers are made of stainless steel, have increased reliability and wear resistance.

Have difficulties choosing or haven’t found what you are looking for?Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

ERGA product portfolio includes different models of WetMag self-discharging wet magnetic separators with operating zone width from 1500 to 2500 mm. Customized solutions can be designed according to the order requirements.

| Model | Dimensions of the drum operating part, mm | Separated material size, mm | Magnetic induction, mT | Capacity, m³/h** | Mass, kg |

|---|---|---|---|---|---|

| WetMag 90х150 | 900х1500 | 0,6 | 180-400 | 60-80 | 2500 |

| WetMag 90х150 P | 900х1500 | 0-3 | 180-400 | 60-80 | 2500 |

| WetMag 90х150 PP | 900х1500 | 0-1 | 180-400 | 60-80 | 2500 |

| WetMag 90х250 | 900х2500 | 0-6 | 180-400 | 100-160 | 4100 |

| WetMag 90х250 P | 900х2500 | 0-3 | 180-400 | 100-160 | 4100 |

| WetMag 90х250 PP | 900х2500 | 0-1 | 180-400 | 100-160 | 4100 |

| WetMag 120х300 | 1200х3000 | 0-6 | 180-400 | 250-350 | 6200 |

| WetMag 120х300 P | 1200х3000 | 0-3 | 180-400 | 250-350 | 6200 |

| WetMag 120х300 PP | 1200х3000 | 0-1 | 180-400 | 250-350 | 6200 |

| WetMag 150х200 | 1500х2000 | 0-6 | 180-400 | 200-275 | 5900 |

| WetMag 150х200 P | 1500х2000 | 0-3 | 180-400 | 200-275 | 5900 |

| WetMag 150х200 PP | 1500х2000 | 0-1 | 180-400 | 200-275 | 5900 |

| WetMag 150х300 | 1500х3000 | 0-6 | 180-400 | 300-410 | 6600 |

| WetMag 150х300 P | 1500х3000 | 0-3 | 180-400 | 300-410 | 6600 |

| WetMag 150х300 PP | 1500х3000 | 0-1 | 180-400 | 300-410 | 6600 |

** Average capacity value is given as it will depend on separated material size and density. Capacity values are given for magnetite.

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- lining

- bearings

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor