Air separator Resoline Air Flow

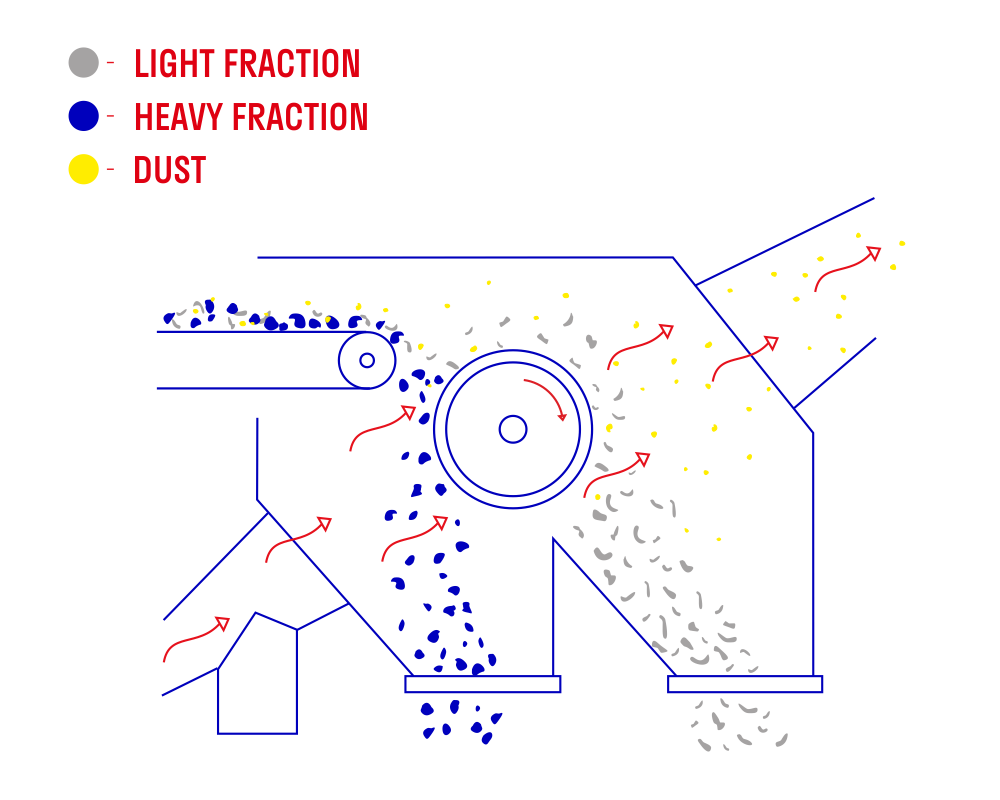

Air separation complex for separation of heavy fraction from MSW (glass, stones, metals, bones, etc.) with efficiency up to 98%

-

Separation/cleaning efficiency up to 98%

-

Adjustable separation parameters

-

High throughput

-

Low power consumption

-

No need to replace filters and zero emissions of dirty air into the atmosphere

-

Easy to operate and maintain

-

Ecofriendly and safe

-

Dry separation method

Operation Principle

Industries

Municipal solid waste

The recycling of municipal solid waste for fuel RDF is a young but rapidly growing industry. Mixed waste consists of organic and inorganic materials, among which there are many steel inclusions that can damage the processing equipment and are useless in the final fuel production process. ERGA offers separators for RDF fuel production, performing a cycle to remove metal inclusions from unprepared raw materials.

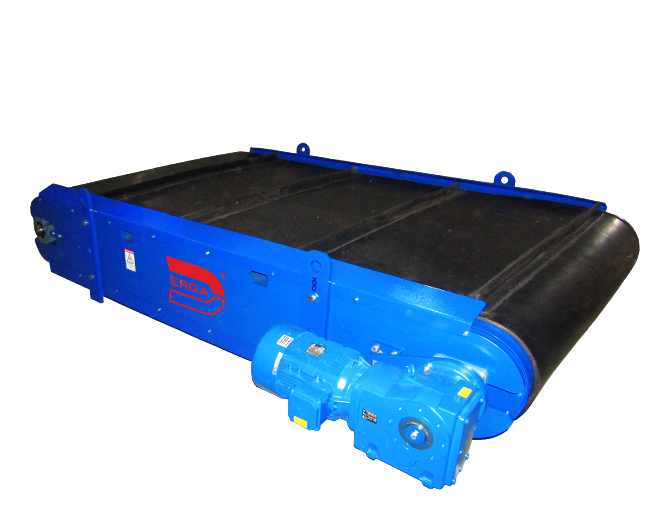

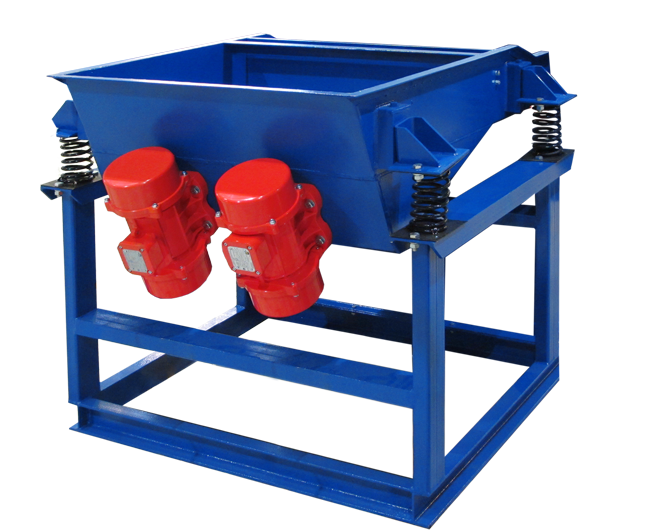

Air separator Resoline Air Flow

The air separation complex consists of acceleration conveyor, air separator, cyclone and fan blower installed on one support frame. The air separator, cyclone and blower are interconnected with a system of air ducts forming a closed air cycle. Downstream the air separator, air moves through the cyclone, where it gets cleaned and enters the blower, from where it is then fed into the air separator. Thus, the complex works without filters and ensures no emissions of dirty air into the atmosphere.

Features of our air separators

Separation/cleaning efficiency up to 98%

The air separator has a sufficient number of settings required for selecting individual separation mode depending on the requirements for the final product. Intuitive adjustment mechanisms help personnel without special knowledge to set up equipment and achieve up to 98% separation efficiency.

Easy to operate and maintain

Simple settings, robust design with easily replaceable components and time-tested solutions ensure trouble-free operation of the complex. Equipment components are adapted to the requirements of heavy duty operation and successfully tested in the most severe modes and various climatic conditions.

Application

Easily adjustable equipment design air separator allows for efficient separation of materials with different density and content of heavy inclusions. Resoline Air Flow separator shows excellent performance in coping with such tasks as:

- obtaining prepared RDF fuel during the processing of municipal solid waste;

- cleaning of MSW from stones, glass, metal, etc.;

- separation of woodworking waste from metal;

- separation of plastic from cullet;

- extraction of film, foil and polystyrene from construction debris;

- removal of inert materials to protect secondary grinders;

- separation of dry materials by density;

- separation of poorly ground materials by density.