Zig zag air separator (pneumatic separator) ERGA ZZFlow

Zig zag air separators (pneumatic separators) are used for dedusting and dry separation of materials into light and heavy fractions by size, density, and shape

-

Separation/cleaning efficiency up to 99%

-

High throughput

-

Adjustable separation parameters

-

Low power consumption

-

No need to replace filters and zero emissions of dirty air into the atmosphere

-

Easy operation

-

No costs for water and drying of material

-

Dry separation method

-

Ecofriendly and safe

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

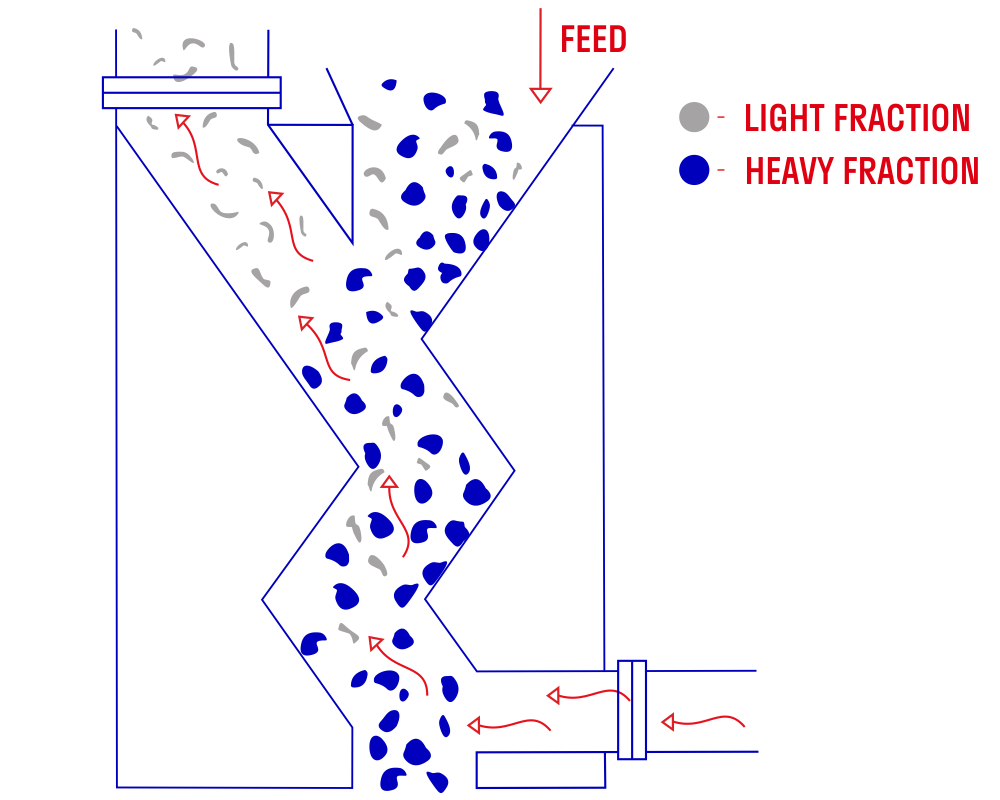

Operation Principle

Industries

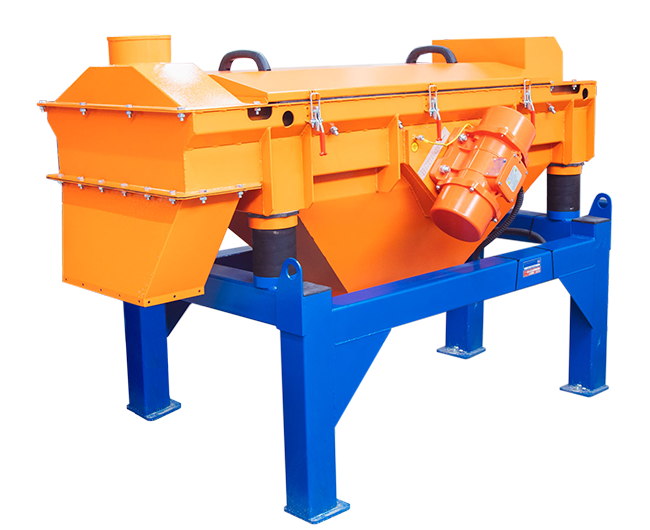

Zig zag air separator (pneumatic separator) ZZFlow is designed for simultaneous dedusting and dry separation of materials into light and heavy fractions by size, density, and shape with up to 99% efficiency.

- Closed air circuit: no filters and compact footprint

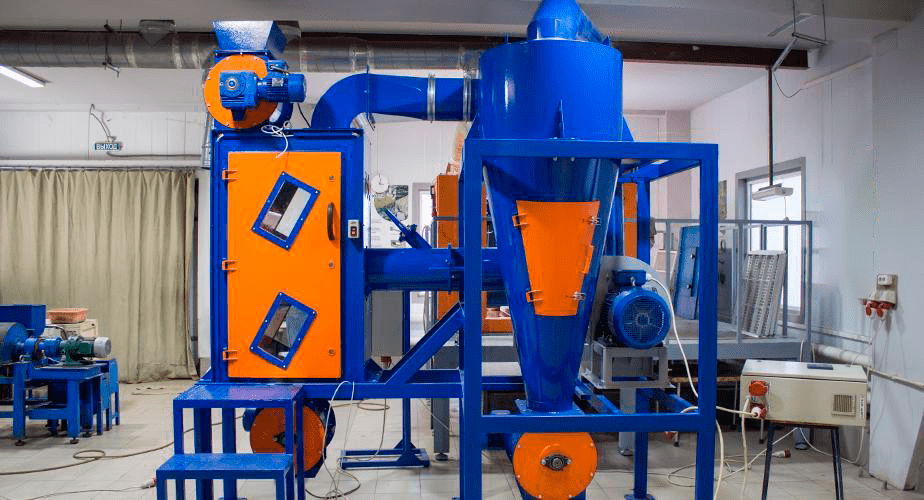

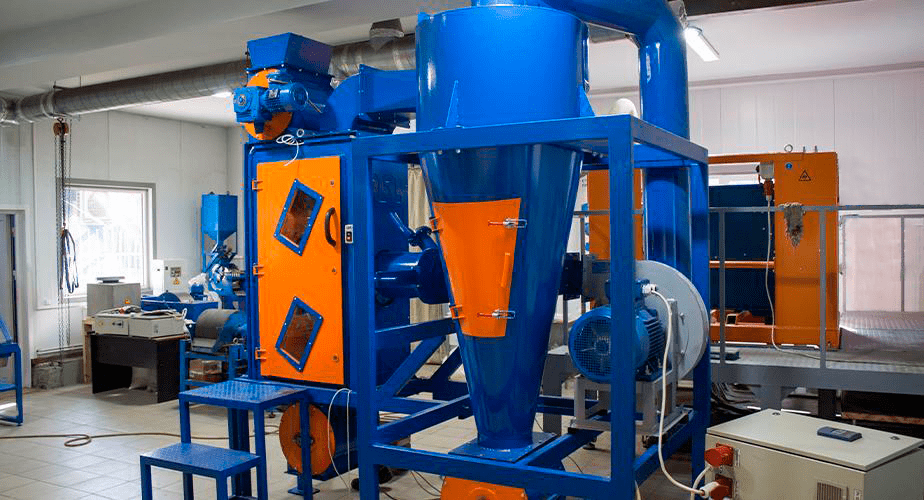

The machine is designed as a mini-plant (ZZFlow separator, cyclone and fan) with closed air circuit: air purified from the product leaves the cyclone and enters the fan, from where it enters ZZFlow separator, forming closed air cycle. As a result, the separator works without filters and has smaller footprint*.

* unlike open-circuit air separators

- Dry separation method: pure economy!

Zig zag air separator allows for replacement or supplement existing equipment, improving the quality of feed material with less power consumption and no time and money spent on water and drying**.

** comparing to wet separation method

- Separation/cleaning efficiency up to 99%

Separation mode is selected depending on material and requirements to end product. Optimum selection of the working chamber of the ZZFlow separator and air flow parameters allow for 99% separation efficiency and purity of feed material.

- Easy operation

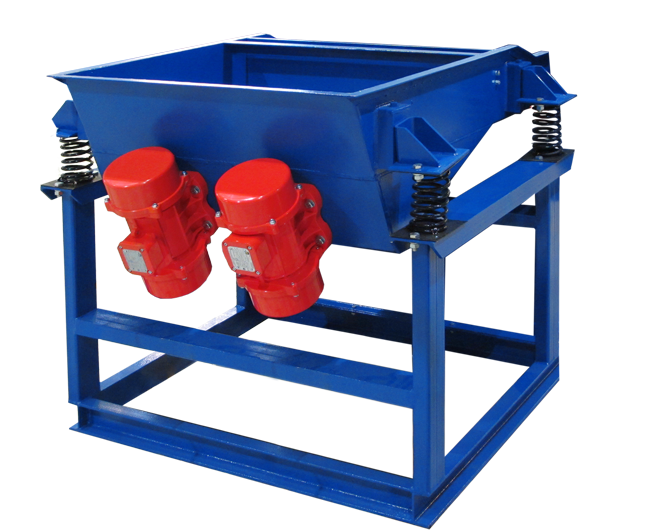

Easy to operate, without quick-wear mechanisms and vibration loads, ZZFlow air separator works continuously not requiring special attention from personnel.

- Application industries

Recycling:

- PET: label removal, paper from PET flakes;

- Shredded cable: separation of copper and aluminum from PE/PVC insulation;

- MSW (municipal solid waste): heavy fraction separation (stones, glass, metal, etc.); light fraction separation (film, paper, fabric);

- Glass cullet: glass cleaning from light fraction (film, label removal, dust);

- Tire granulate: separation of textile, dust, rubber granulate;

- WEEE (Waste of electronic and electrical equipment): recovery of plastic, rubber, fabric;

- Wood chips: removal of paper, textile, fabric; recovery of metal, stones, glass;

- Plastic granulate: removal of dust, fluff, fine particles;

- RDF/SRF fuel: separation of light fraction from waste.

Food industry:

- Grain: separation of mineral impurities from processed raw materials, separation of leaf from stem, husk from whole seeds;

- Sugar, table salt, flour and grain, starch, dairy products, tea, gelatin, vegetables, cocoa powder and chocolate chips: removal of residues of polypropylene bags, sack stitching threads, dust;

- Spices, herbs and plants (pharmacy): removal of dust, threads.

Mining, construction and demolition, metallurgy:

- Removal of dusty fraction (dolomite, feldspar, marble chips, etc.), separation by shape (mica, vermiculite, etc.) or specific gravity (chromite ore, metal ceramics, powder metallurgy).

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced models of ZZFlow air separators are given in the table. Customized solutions can be designed according to the order requirements.

| Model | Capacity*, t/h | Power, kW |

|---|---|---|

| ZZFlow 100х400 | 0,3-0,7 | 7,5 |

| ZZFlow 150х600 | 0,6-1,2 | 11 |

| ZZFlow 150х800 | 1,2-3,5 | 14 |

| ZZFlow 200х1000 | 3,2-6,4 | 18 |

| ZZFlow 250х1200 | 5,4-11 | 25 |

| ZZFlowg 250х1800 | 7,2-15 | 28 |