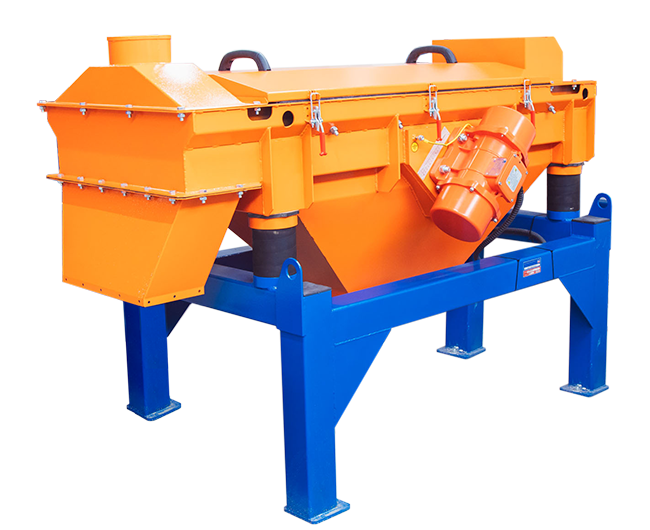

ERGA VS vibrating screen

ERGA VS vibrating screen for continuous screening of bulk materials into several fractions by size

-

Efficient screening into 4 fractions

-

Robust design and high capacity

-

Quick replacement of screens

-

Optional aspiration

-

Easy assembly and operation

-

Wide range of options and settings

-

Efficient operation 24/7 in harsh conditions

-

Easy integration in line

-

Reliability and durability

-

Equipment guarantee

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

Industries

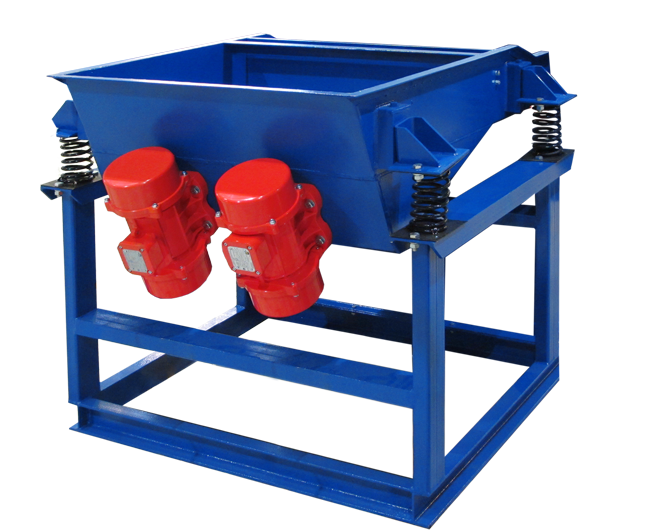

ERGA VS vibrating screens (vibratory screens, unbalanced throw screens) are used for classification of bulk granular materials and dewatering.

- Efficient screening into 4 fractions

ERGA VS screens are designed with 1-3 decks for screening into 4 fractions and getting saleable products with sizes from 60mm to 5mm depending on design specifications.

They are equipped with screening surface of various mesh sizes and shapes. Screen materials are also selected depending on product properties and can be made of perforated steel or aluminum sheet with round, square or slotted mesh; for operation with difficult clay or sticky materials polyurethane screen panels are used.

- Robust design and high capacity

ERGA vibrating screens have solid frame and housing, unbalanced type of vibration exciter system ensures high throughput, screen inclination angle up to 15° increases the screening rate.

- Easy installation and operation

Simple and robust design of ERGA VS screen with easy assembly and low maintenance costs provides easy access to operating parts and simple cleaning. Remote control of the screen operation makes control and operation settings easier. Operating parts made of wear-resistant high-strength materials increase service life.

- Wide range of options and settings

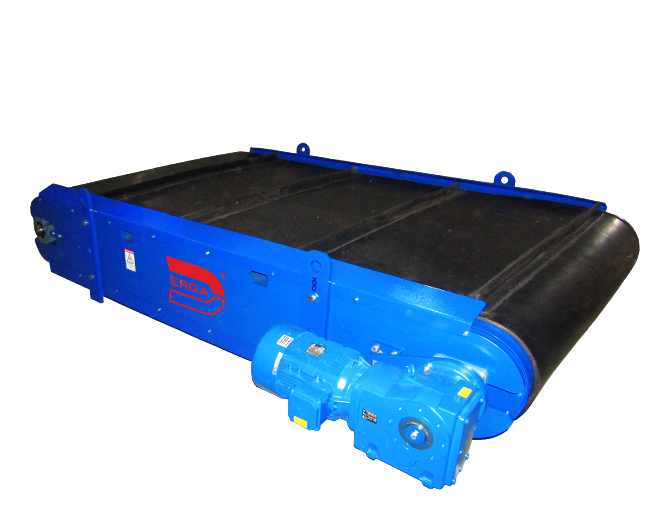

ERGA VS vibrating screens are part of processing lines in various industries: food, mining, construction, metallurgy, recycling, chemical. Vibrating screens can have carbon or stainless steel construction, enclosed or open design, they are optionally connected to aspiration or water spraying systems. They can also be equipped with hoppers and vibratory feeders.

- Efficient operation 24/7 in harsh conditions

The equipment is designed for both periodic and continuous operation, even in harsh conditions.

- Have difficulties choosing or haven’t found what you are looking for?

Contact us in any convenient way and we will select suitable solution for you.