Optical separator GlasSortika

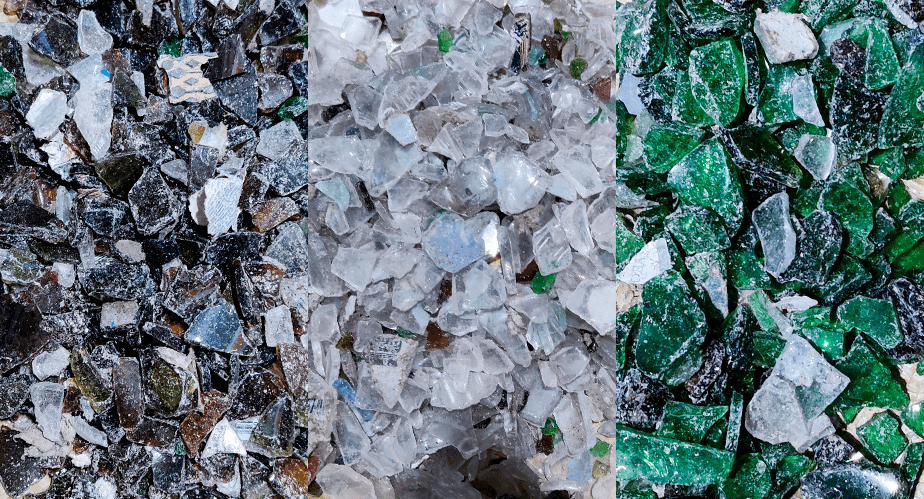

Optical separator GlasSortika for final cleaning of glass scrap from impurities and separation by color

-

Obtaining first grade glass scrap

-

24/7 continuous operation

-

Easy and fast customization

-

Two separation stages in a single housing

-

Continuous diagnostics and automatic protection system

-

Performance confirmation at ERGA Innovation Centre

Optical separator GlasSortika is intended for cleaning and separation of glass scrap secondary material with sizes varying from 5 to 50 mm and separation efficiency up to 99.99%.

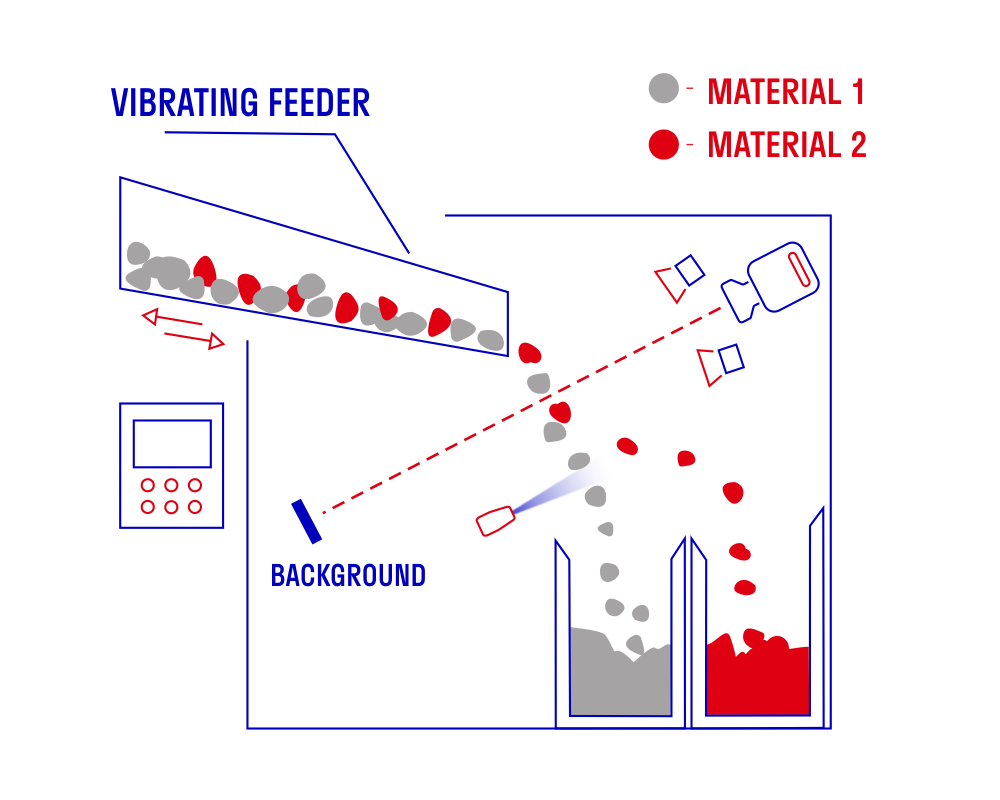

- Obtaining first grade glass scrap

The individual sorting program is selected depending on the characteristics and composition of the feed material. Fine-tuning the parameters by which rejection is performed: color, transparency, shape, time and duration of valve opening; intensity of background illumination allows to achieve up to 99.99% efficiency of separation and purification from organics, ceramics, stones, metal, mirrors, porcelain, concrete, bricks, slag.

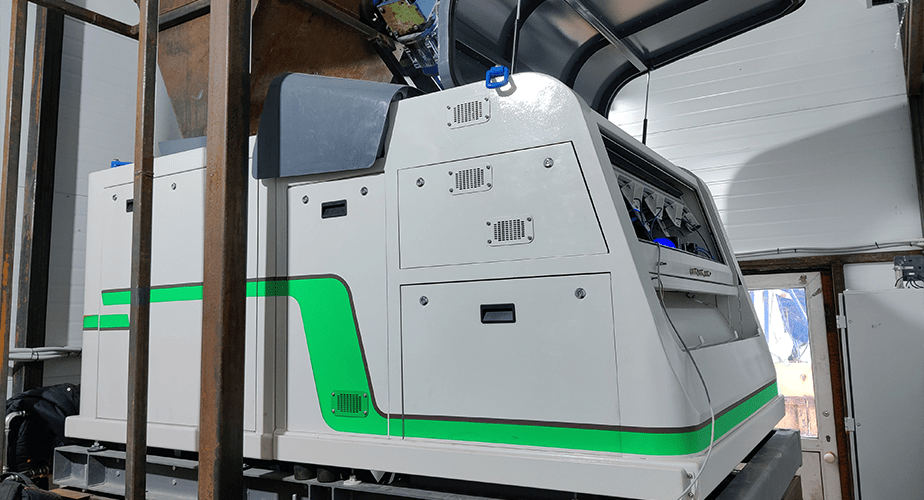

- High reliability

The optical separator is specially designed for reliable handling of abrasive glass scrap. A quick-release metal liner is installed on the surface in contact with the material, the boxes with electronics are protected from external dust and moisture.

- Convenient and fast equipment setup

The control panel is a 17-inch high-definition touch screen, which is convenient for setting the separation mode. The developed software with intuitive user interface allows to quickly customize the equipment for individual material characteristics and has 3 levels of access (worker, engineer, service technician). In addition to adjusting the basic operating parameters of the product, the settings of the separation parameters for each type of material can be saved.

- Three products on one equipment

Installation of the second level of rejection allows to obtain separation 3 fractions in a single stage differing in color, shape, and transparency or to clean the material as much as possible in case of high contamination with impurities. This will reduce the amount of equipment used, including conveying equipment, and improve the quality of material separation with lower financial and time costs.

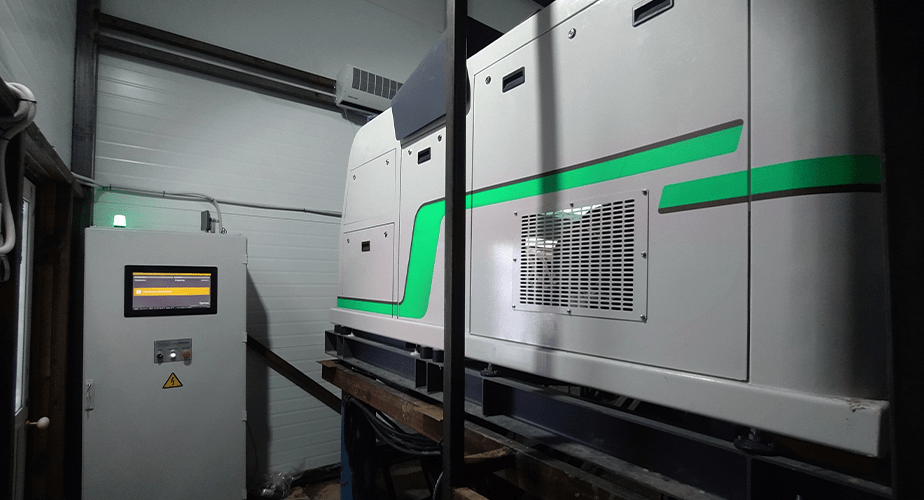

- Diagnostics

The diagnostic system continuously monitors the main parameters of equipment operation (number of valve actuations, system pressure, temperature in the electronics boxes, material sticking in the detection zone). In case of emergency mode, the protection system is activated, which stops the operation of the equipment and emits a visual and audible signal to the operator.

- Remote monitoring and control

Remote monitoring and control system allows to monitor separation parameters and promptly adjust the equipment to changes in the characteristics of incoming raw materials (changes in hue, transparency, composition, and size of inclusions).

- Purpose

- Removal of organics, stones, ceramics, metal, plastics, mirrors, porcelain, concrete, bricks, and slag from glass scrap

- Separation of glass scrap by color: brown B, green G, colorless C

- Extraction of glass scrap from organic waste of waste treatment plants (compost)

- Recycling of slag after MSW incineration

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced models of ERGA GlasSortika optical separators are given in the table. Customized solutions can be designed according to the order requirements.

| Model | Qty of rejection stages | Operating area length, mm | Power, kW | Dimenstions (LxWxH),mm |

|---|---|---|---|---|

| Glas Sortika 600-1 | 1 | 600 | 4 | 600х515х1100 |

| Glas Sortika 1200-1 | 1 | 1200 | 6 | 1350х1200х1570 |

| Glas Sortika 600-2 | 2 | 600 | 6 | 1100х1100х3200 |

| Glas Sortika 1200-2 | 2 | 1200 | 8 | 1800х1100х3200 |

To ensure continuous operation of the equipment, you can additionally order a spare parts kit:

- Lining

- Wiper of the cleaning brush

- Block of ejectors

For this type of equipment it is possible to integrate REMOS remote monitoring system, which allows you to monitor the state of the separator in real time.

Available options include: