Laboratory electrostatic separator ERGA ELKRON ESS

Electrostatic corona drum separator for dry separation of materials with different electrical properties

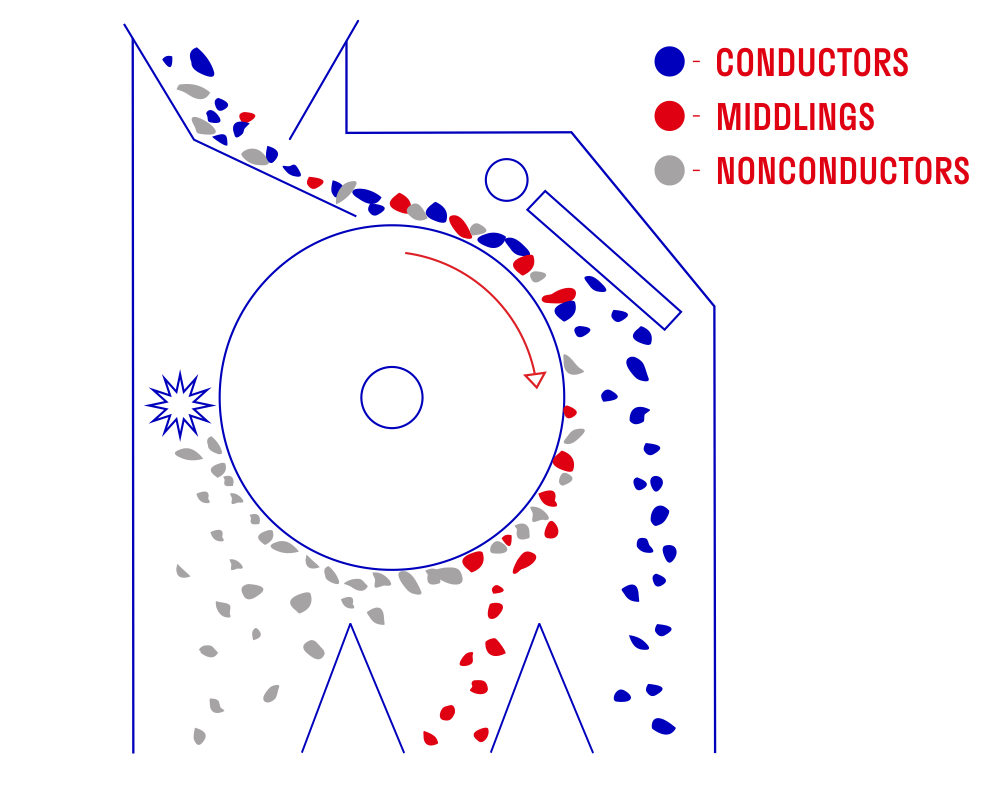

Operation Principle

Industries

Laboratory electrostatic separator ERGA ELKRON ESS is designed for studying applicability of dry separation processes for materials with different electrical properties. ERGA ELKRON ESS provides recovery of metal and mineral particles with size from 0.040 to 8 mm and up to 99.8% separation and cleaning efficiency of feed material.

- 2 in 1: electrostatic and triboelectrostatic mode

ERGA ELKRON ESS separator differ from its analogs with capability to operate both in electrostatic mode for separating materials by electrical properties and in triboelectrostatic mode for separating dielectrics by tribocharge sign.

- Separation/cleaning efficiency up to 99.8%

Required separation mode is selected depending on feed material. Fine adjustment of the collecting electrode rotation frequency, position and voltage of the deflecting and corona discharge electrodes, position of the splitters ensures up to 99.8% efficiency of separation and cleaning of the feed material.

- Wide range of separation mode settings

Rotation frequency of ELKRON ESS collecting electrode (320 mm diameter) is adjustable. The presence of infeed hopper with a slide gate and a vibrating feeder in its design allows for adjustment of the process capacity and ensures monolayer material feed. Fine setting of splitters provides accurate separation of fractions by electric properties.

- Automatic cleaning of electrodes

Automatic cleaning of collecting and corona discharge electrodes is automatic without personnel involvement. Continuous removal of nonconductors in automatic mode improves separation quality.

- Touch Screen intuitive control

The control panel is a 7-inch high-definition touch screen with user-friendly interface: 3 levels of access to settings (operator, engineer, service specialist). In addition to settings of main operating parameters of the product, it is possible to save settings of separation parameters for every type of material.

- Applications:

- Separation of plastic from metal;

- Recycling of electric appliances;

- Recycling of LED lamps;

- Cable recycling;

- Recycling of PET bottles;

- Recycling of printed circuit boards;

- Recycling of plastic window profiles;

- Recycling of used tires.

- Materials for dry concentration

- Precious metal ores of (Au, Ag);

- Non-metallic ores and materials (quartz sand, feldspar, etc.);

- Non-errous and rare metal ores of (titanium-zirconium, tin-tungsten, columbite-tantalite, etc.);

- Diamond-bearing ores.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Laboratory models of ERGA ELKRON ESS electrostatic separators are custom-made and designed according to the order requirements.

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- roll

- bearings

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Splitter, flap position sensor

- Access to complete information about operation of the machine (operation / idle, operating modes, error decoding, position of magnetic rods, cleaning period)

- Gas analyzer (ozone sensor)

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor