Resoline incineration bottom ash recycling line

Line for ferrous and nonferrous metal recovery from incineration bottom ash

-

Industry: MSW treatment

-

Raw material: bottom ash from MSW incineration plant

-

Size of feed material: 0-100 mm

-

Capacity: 15 t/h

-

Fractional composition of end products:

-

Ferrous metal: 0-10; 10-100 mm;

-

Nonferrous metal: 0-10; 10-100 mm;

-

Nonmetal: 0-2; 2-10; 10-100 mm

-

Obtaining aluminum slag (metallic aluminum)

-

Project payback: less than 1 year

-

Commissioning: May 2017

Industries

Incineration bottom ash recycling line ensures ferrous and nonferrous metal recovery and sorting into fractions.

- Problem description:

Solving the problem of overfilled landfills, reducing the volume of waste disposal is a crucial task for municipal solid waste management industry. Waste incineration plants or waste-to-energy plants (WTE) can neutralize and dispose of municipal solid waste, simultaneously generating heat and electricity and receiving residues in the form of bottom ash and fly ash.

Bottom ash makes up 20-30% of the total mass of incinerated waste, of which steel and ferrous metals account for up to 10-12%, and nonferrous metals for up to 2-5%, of which 2/3 is aluminum.

The percentage of ferrous and nonferrous metals in the ash depends on MSW composition and applied process. Ferrous and nonferrous metals do not lose their valuable properties after incineration and are successfully reused at refineries and smelters. The mineral fraction is used in construction and road building industries. More and more countries impose a ban on disposal of waste, which includes valuable recyclables (ferrous and nonferrous scrap).

Based on implemented laboratory tests ERGA specialists developed a process solution for complex processing of incineration bottom ash in accordance with the Customer specifications.

- Automatic turnkey complex solution

ERGA implemented a full range of services from design to installation and commissioning of IBA recycling line on the territory of the Customer's landfill.

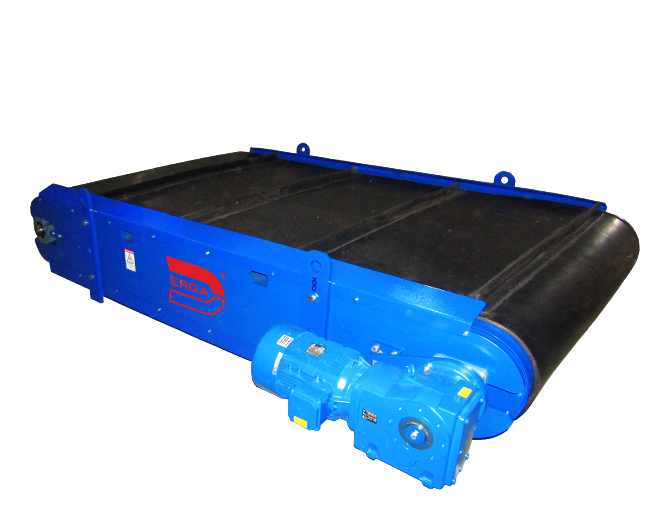

All separators in the line are equipped with automatic cleaning system and provide recovery of fractional ferrous and nonferrous scrap, which is suitable for further profitable sale.

- Obtaining saleable ferrous and nonferrous scrap

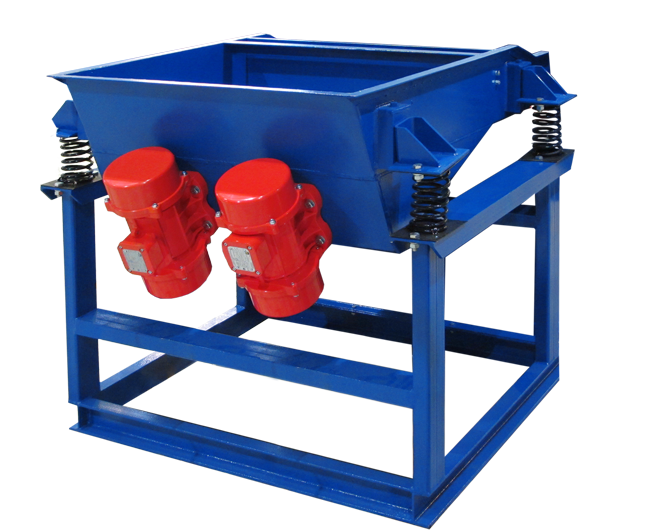

Incineration bottom ash is fed from the hopper into ERGA GB trommel, where it is cleaned from the ash, followed by separation into fractions of 0-10 mm and 10-100 mm. Fines not exceeding 10 mm are conveyed for downstream separation and recovery of ferrous and nonferrous metals. 10-100 mm metal fraction is further sorted using automatic suspended iron separator ERGA SuspendMag A and powerful magnetic drum separators ERGA DrumMag. At the final stage, nonferrous metals are extracted with eddy current magnetic separator ERGA EddyFlow.

- Green and safe technologies

All line components have low power consumption and also help to reduce power consumption in further production of metals and other materials, increase metal recycling rate and reduce consumption of natural resources and amount of slag disposal in landfills. The equipment is made in compliance with all safety requirements and standards.

- Have difficulties choosing or haven’t found what you are looking for?

Contact us in any convenient way and we will select the most suitable solution to you.

- Secondary ferrous metals are used in the production of sinter and electroferroalloys, cast iron and steel, iron castings and nonferrous metals, as well as for consumer goods.

- Secondary nonferrous metals are used for smelting secondary aluminum alloys, tin bronze, brass and other alloys and steels.

- Pure ash is used in the production of Portland cement and road construction for pavements in car parks, driveways, and for protective coating of landfills.