Optical separators

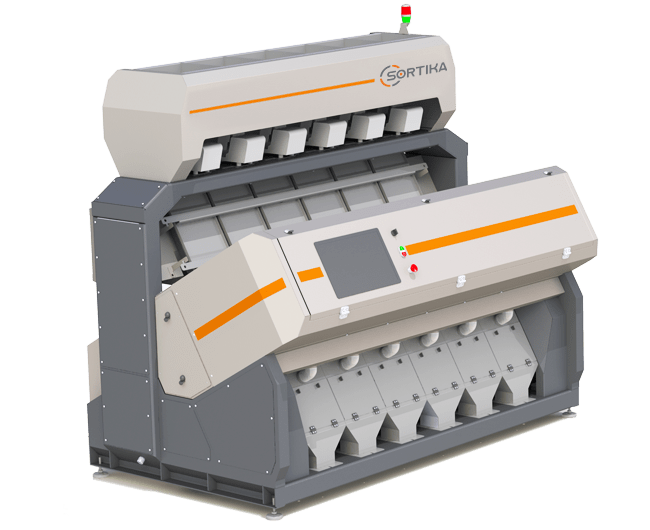

Optical separator LuxSortika VF

-

Separation efficiency up to 99,99%

-

Operation with difficult abrasive materials

-

User-friendly and fast setup

-

Two stages of separation in one housing

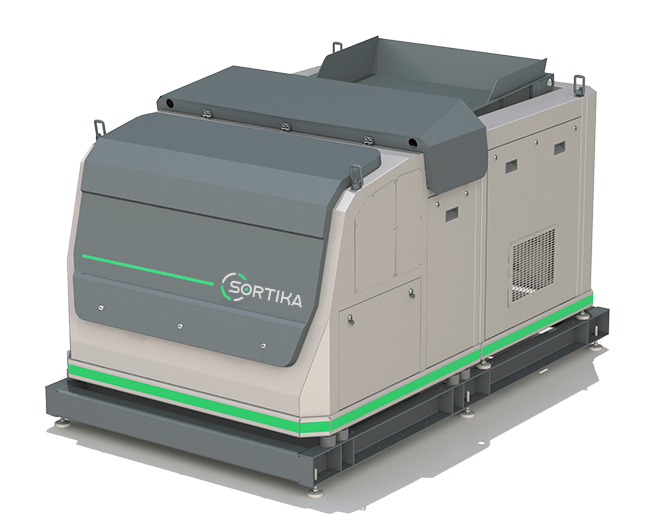

Optical separator GlasSortika

-

Obtaining first grade glass scrap

-

24/7 continuous operation

-

Easy and fast customization

-

Two separation stages in a single housing

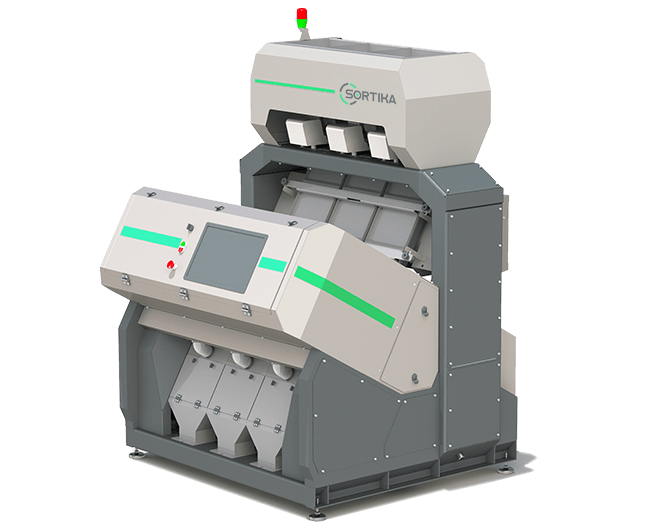

Optical separator LuxSortika CF

-

Efficient separation of minerals less than 10 mm

-

24-7 mineral raw material separation

-

2x productivity increase on the same equipment

-

Up to 3 stages in a single housing

Optical separator ReSortika CF

-

Effective separation of polymers less than 15 mm

-

Production of cleaned recyclable materials

-

Proprietary software with lifetime tech support

-

Upgrade with 3x performance increase

Optical separator LuxSortika BF

-

Efficient separation by mineral composition

-

Preparation of concentrate by dry method

-

Discharge of final tailings

-

Proprietary software with lifetime tech support

Optical separator ReSortika BF

-

Efficient separation by composition

-

Proprietary software with lifetime tech support

-

Effective separation of polymers less than 15 mm

-

2 stages of impurity extraction

Optical separators for the mining and processing industry.

Modern optical separators are sorters used for fast and automatic separation of materials by color, which are used in the processing of a variety of bulk materials, distinguishing foreign particles from the bulk. The principle of operation of an optical sorter is to pass a mixed mass of waste through a system of chambers that detect color contrast and material type. The control system then directs the desired elements into the appropriate containers for further processing. Ready-made solutions from ERGA are used in the mining industry or in glass recycling.

Distinctive features of ERGA optical sorters:

- Separation efficiency up to 99.99%

- Sorting of abrasive materials

- Dry separation method

- Automatic cleaning

Optical separators for the mining industry

Through efficient cleaning, our optical separators increase the quality of the finished product or help to obtain high quality concentrates.

Areas for which we have ready-made solutions:

placer and bedrock precious metal deposits: gold-quartz, gold-sulphide, silver-gold;

ores: limestone, quartz, dolomite, talc, magnesite, marble, chloride salts, sylvinite ores.

Separators for glass recycling and processing

Recycling takes place in two stages: separation by color and density. After the initial separation, the particles pass through a second scanner to divide the glass into fragments of the same size. Unidentified particles are sent for re-separation, achieving an efficiency of 99.9%. The sorting program allows cleaning or sorting by color, shape, transparency. The raw material can be a mixture of stones, ceramics, metal, plastic, mirrors, porcelain, concrete, bricks, slag.

Areas for which we have ready-made solutions:

Placer and bedrock precious metal deposits: gold-quartz, gold-sulphide, silver-gold;

Ores: limestone, quartz, dolomite, talc, magnesite, marble, chloride salts, sylvinite ores.