Optical separators manufactured by ERGA: modern waste recycling technologies

- #optical separators

- #PET bottles

- #waste recycling

- #Sortika

Every month, hundreds of thousands of PET bottles (polyethylene terephthalate) are thrown into the waste in large cities. The share of PET containers in the total waste is from 3% to 10%, depending on the time of year.

Together with other household waste, tons of plastic end up in landfills, poisoning the soil and air with toxic substances and taking about 150 years to decompose completely. However, PET containers are successfully recycled and can be a source of quality raw materials. By generating monetary income and preventing environmental pollution, this will help reduce the amount of waste sent to landfills.

Based on the global practice of PET recycling, ERGA conducted research in 2023. Which focused on sorting PET bottles and subsequently PET flexes to remove polymers of different compositions and color separation.

During the study, the optimal recycling technology was selected, taking into account the peculiarities of secondary material, which has a high percentage of clogging with other polymers and foreign impurities (glass, black and non-ferrous metal, wood, etc.).

The result of this research allows us to obtain a concentrate of transparent-blue and/or brown-green PET-flex suitable for further manufacture of various types of goods, such as:

- packaging products and materials

- clothing and footwear;

- synthetic fabrics (nylon, polyester);

- insulation materials and fillers (hollowfiber, padding polyester, fleece);

- interior items, furniture, fittings;

- household utensils (brushes, brooms).

Preliminary studies were conducted at the ERGA Innovation Centre on industrial optical separators, ERGA ReSortika.

ERGA Innovation Centre includes both laboratory and industrial models of magnetic, electrostatic, gravity, air, optical separators and metal detectors produced by the company. Where customers are given the opportunity to model an effective technology for recycling secondary raw materials and evaluate the efficiency of the offered equipment in practice.

In the technology of PET separation by color and composition, optical separators ERGA ReSortika BF for sorting PET bottles and ERGA ReSortika CF for sorting PET flex work in the visible (VIS) and near infrared (NIR) ranges. This allows the polymer type to be determined and separated by composition with an accuracy of 5-99 %.

ERGA ReSortika BF optical separator for PET bottles:

ERGA ReSortika CF optical separator for PET flex:

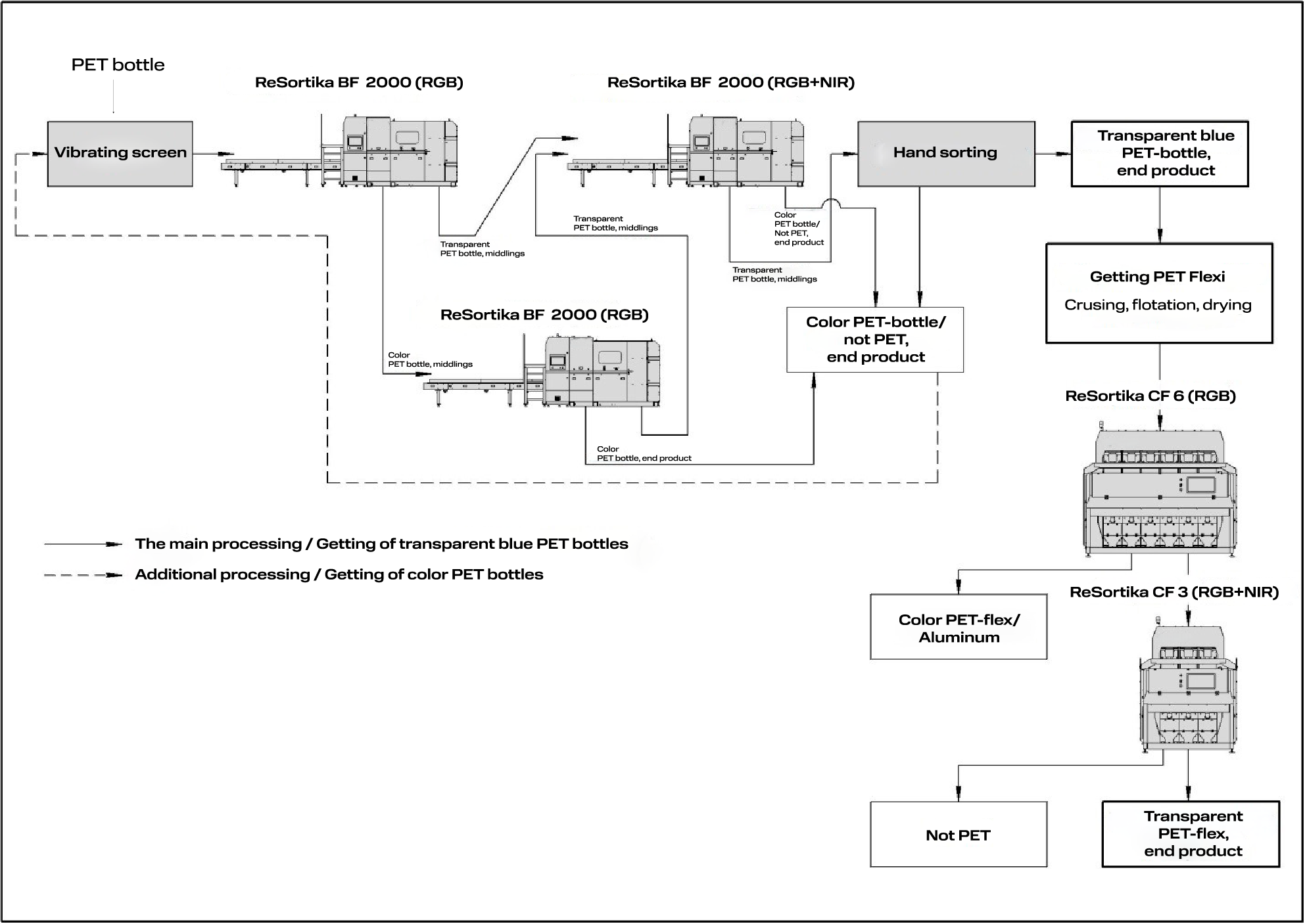

The result of the research work was the design of the optical sorting section of the PET processing line with a capacity of up to 3.5 tons per hour for the incoming raw materials to obtain the final product in the form of PET flex. This is suitable for further manufacture of various types of goods.

Scheme of in-line optical separators ERGA ReSortika

Besides working on the acquisition of refined PET-flex, ERGA is also involved in the creation of technology for extensive recycling of secondary glass, commonly known as cullet. Recycling of glass products is becoming more and more on demand. Every year, the share of recycled glass used as a component of the charge for the production of containers and glass fiber increases, which saves natural resources and makes the production of new products cheaper.

The main task of cleaning and sorting cullet is the most complete extraction of a wide range of foreign inclusions and separation of cullet by color in order to obtain 1st grade glass, suitable for further glassmaking.

In 2023, a project on optical separation of cullet was successfully implemented at one of the enterprises. ERGA has created and implemented a solution leveraging ERGA GlasSortika 1200 optical sorter, which can sort up to 10 tons of material per hour. The solution is designed for extraction of impurities – minerals, organics, stones, ceramics, metals and can operate in color separation mode for colorless, brown and green glass. Compared to foreign analogues, the equipment can fulfil its task in the technological line without a drying drum and can cope with the work at high humidity of glass sludge round the clock, regardless of the season.

Design-engineering works and many years of experience in the production of equipment for glass sludge allowed our specialists to develop and design a line with a capacity of up to 10 tons per hour to produce 1st grade glass. This includes screens, magnetic, eddy current, air, optical separators, and classifiers manufactured by ERGA.

Nowadays, the importance of sorting solid municipal waste (MSW) has significantly increased. With increasing volumes of recycling, the question of the automation of this process inevitably arises. One of the key technologies in this process is waste sorting in the visible (VIS) and near-infrared (NIR) spectrums.

To solve the complex task of sorting mixed waste ERGA ReSortika BF 1400 optical separator was designed and manufactured using spectral analysis and artificial intelligence technologies. The equipment efficiently extracts from mixed municipal solid waste such useful materials for recycling as PET, PP, LDPE, HDPE, PVC, waste paper, glass, tetra pack and aluminum. The separator can be integrated into existing or projected process lines for waste processing plants.

ERGA invites enterprises and design organizations to cooperate with us in order to jointly find solutions for the sorting of secondary raw materials.

Modern innovative magnetic, air, eddy current, and optical separation technologies, developed and manufactured by ERGA, form the basis for enhancing the efficiency of secondary raw material recovery.