ERGA MM magnetic couplings

ERGA MM magnetic couplings transmit torque from the driving shaft to the driven one with magnetic field

-

Design with in-house produced NdFeB or SmCо permanent magnets

-

No leaks, contamination and maintenance

-

No power consumption

-

Minimum service life 10 years

-

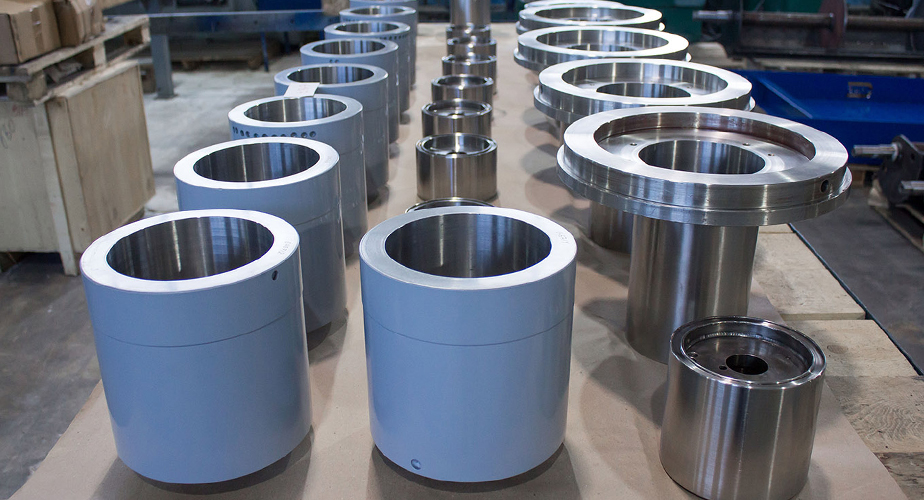

Over 1000 types of magnetic couplings manufactured

-

Ideal for application in explosive media

-

Experience since 2001

-

Retrofitting and repair of import and Russian equipment

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

Industries

ERGA MM magnetic couplings are widely used in circulating pump systems for pumping hazardous and corrosive liquids in chemical, oil and gas, food and other industries.

- Design with in-house produced NdFeB or SmCо permanent magnets

Magnetic field is generated by (NdFeB and SmCo) permanent magnets installed in the driving and driven half- couplings. Protective metal or ceramic containment shroud between the half-couplings ensures tightness of the pumped product. For application at temperatures of the pumped liquid up to 150 ° C neodymium magnets are used, up to 350 ° C - samarium-cobalt magnets. The use of high-coercivity permanent magnets provides compact couplings and high torque values in limited space.

- No leaks, contamination and maintenance

ERGA MM couplings ensure completely hermetic solution for pumping equipment, eliminating any leaks and keeping the pumped product clean unlike mechanical seals. Application of magnetic couplings provides reduction of costs for maintenance, besides, such couplings do not consume any power for operation.

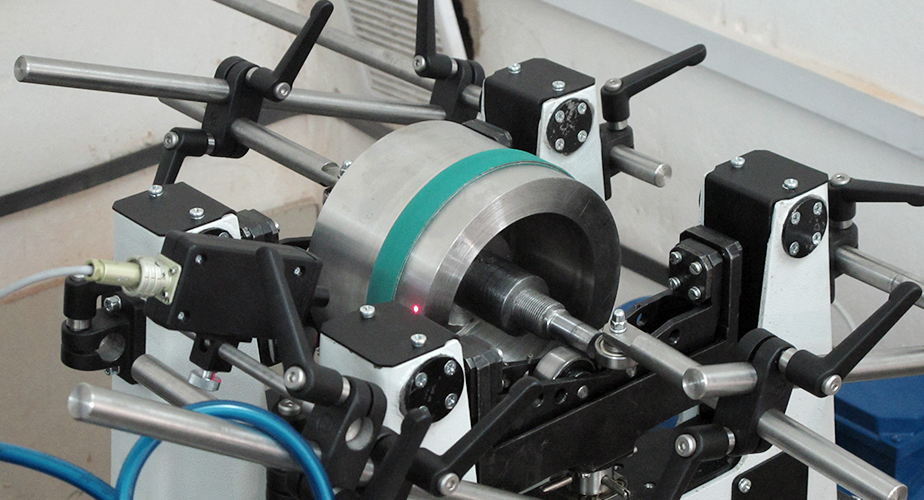

All manufactured shrouds for couplings undergo thorough quality control test with final pressure test exceeding the operating pressure by 25% to identify defects and ensure stable operation of products under load.

- Minimum service life-10 years

Permanent magnet couplings have no wearing parts; their service life is determined by service life of the magnets (minimum 10 years).

- Ideal for application in explosive media

ERGA MM magnetic couplings provide safety of service personnel in operation with aggressive, highly toxic, explosive, corrosive liquids. Application of magnetic couplings eliminates destruction of shafts and unit components during shock braking, ensuring environmental safety and guaranteeing safety at work. The production process is organized using ISO 9001-2015 quality management standards.

- Retrofitting and repair of import and Russian equipment

Since 2001 Research and Production Company “ERGA” has been providing services of repair of magnetic couplings, replacement and retrofitting of permanent magnet systems, restoring tightness o couplings and retrofitting couplings of foreign and Russian production.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

With many years of experience Research and Production Company ERGA has capabilities to design, engineer and test UMM assemblies of mixers and agitators. We produce reliable assemblies that work in the toughest conditions in various industries. Magnetic couplings are designed and developed using FEA software system. Many years of experience in engineering and manufacture of magnetic systems using advanced technologies and software allows ERGA to design and manufacture not only standard models, but also customized magnetic couplings of various types and sizes.

General characteristics of ERGA MM couplings:

- Torque from 0.001 to 5000 Nm

- Operating temperature -60 +350°C

- Operating pressure up to 500 atm.

- Up to 60 000 rpm