Optical separator ReSortika BF

Optical sorter supplying secondary materials to a high-speed conveyor to separate materials by composition, color, and shape

-

Efficient separation by composition

-

Proprietary software with lifetime tech support

-

Effective separation of polymers less than 15 mm

-

2 stages of impurity extraction

-

Dry enrichment technology

-

Setup in 3 clicks

-

Affordable and fast service maintenance

-

Performance confirmation at ERGA Innovation Centre

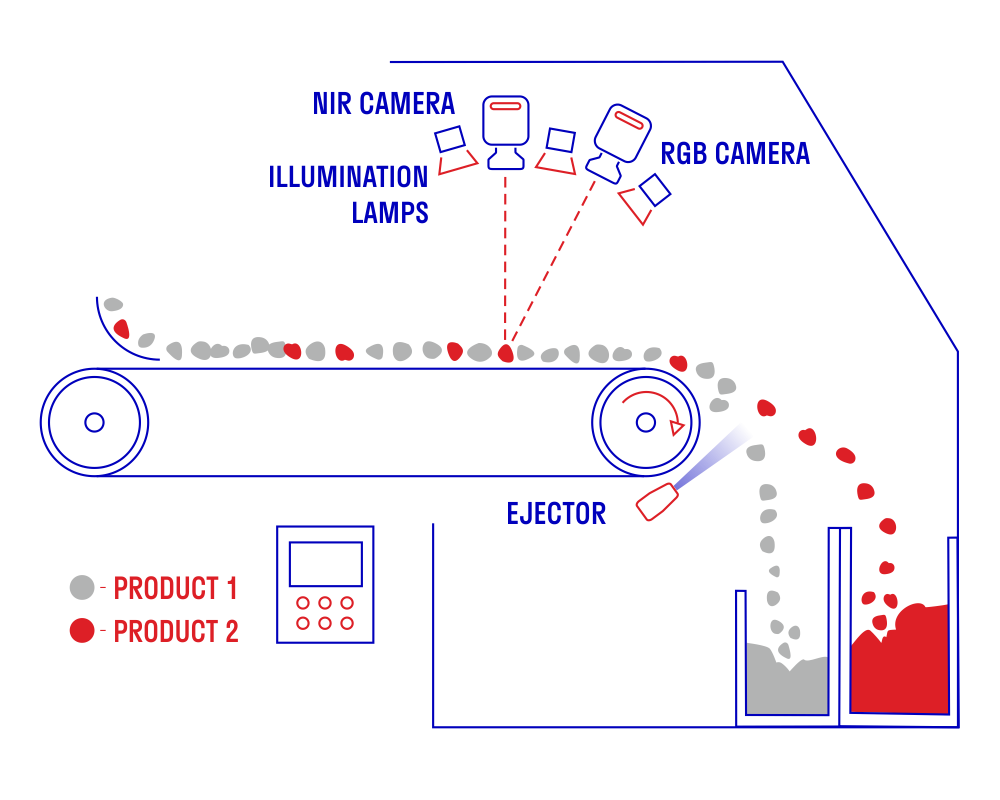

Operation Principle

Industries

Optical separator ReSortika BF is intended for separation of secondary materials with sizes varying from 20 mm to 350 mm and detection efficiency up to 99%.

25 years of experience in the manufacture of recycling equipment

- Fields of application: recycling

- Efficient separation by composition

- Production of cleaned recyclable materials

- Software with lifetime tech support

- Setup in 3 clicks

- Up to 2 stages in a single housing

- Ready-made solutions for high-speed conveyors

- Affordable and fast service maintenance

- Performance confirmation at ERGA Innovation Centre

- Quality improvement

The developed sorting program, which analyzes the spectrum of the material in the near infrared spectrum, is configured according to the characteristics and morphology of the secondary material. Precise adjustment of MSW sorting parameters allows to determine the material composition with an accuracy of up to 99% and perform separation with an efficiency of up to 95% with the output of finished recycled products.

- Convenient and fast equipment setup

The control panel is a 17-inch high-definition touch screen, which is convenient for setting the separation mode. The developed software with intuitive user interface allows to customize the equipment in 3 clicks for individual material characteristics and has 3 levels of access (worker, engineer, service technician). In addition to adjusting the basic operating parameters of the product, the settings of the separation parameters for each type of material can be saved.

- Two separation stages in a single housing

Installation of the second level of nozzles for rejection allows to obtain 3 fractions differing in composition, color, and shape in just one stage of separation. This will reduce the amount of equipment used, including conveying equipment, and improve the quality of material separation with lower financial and time costs.

- Automatic cleaning of the detection area

Automatic cleaning of the splitter blade and conveyor belt eliminates downtime and maintains efficiency without operator intervention and long maintenance stops.

- Detection and rejection units for high-speed conveyors

The developed modules for detection and rejection units can be installed on ready-made high-speed conveyors with working belt widths of 1400, 2000, and 2800 mm.

- Remote monitoring and control

Remote monitoring, diagnostics, and control system allows to monitor separation parameters and promptly adjust the equipment to changes in the characteristics of incoming mineral raw materials (changes in composition, color, and size of inclusions).

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

The serially produced models of ERGA ReSortika BF optical separators are presented in the table. Custom solutions can be developed according to the technical specifications requirements.

|

Equipment model |

Number of rejection stages |

Working area length, mm |

Power, kW |

Overall dimensions (DxWxH), mm |

|---|---|---|---|---|

|

ReSortika ВF 1400-1 (VIS, NIR) |

1 |

1400 |

5,5 |

7024х2188х2246 |

|

ReSortika ВF 2000-1 (NIR) |

1 |

2000 |

7,5 |

7032х2751х2246 |

|

ReSortika ВF 2800-1 (VIS, NIR) |

1 |

2800 |

9,0 |

7032х3560х2246 |

|

ReSortika ВF 1400-2 (Ind) |

2 |

1400 |

6,5 |

7024х2188х2246 |

|

ReSortika ВF 2000-2 (VIS, NIR, Ind) |

2 |

2000 |

8,5 |

7032х2751х2246 |

|

ReSortika ВF 2800-2 (VIS, NIR, Ind) |

2 |

2800 |

10,0 |

7032х3560х2246 |

You can additionally order a spare parts kit to ensure continuous operation of the equipment:

- Conveyor belt

- Lighting module

- Ejector unit

REMOS remote monitoring system can be integrated with this type of equipment, which allows to monitor the separator status in real time.

Available options:

- Access to complete device operation information (operation/idle, operating modes, error decoding, magnetic bar position, cleaning period)

- Power supply status sensor

- Electric motor operation control (if frequency converter is installed)

- Position monitoring sensor for input circuit breakers and contactors

- Equipment downtime control

- Door status control (open/closed)

- Pneumatic system pressure sensor

- Device operating mode (off, on)

- Humidity sensor

- Temperature sensor